Advanced Engineering Plastics

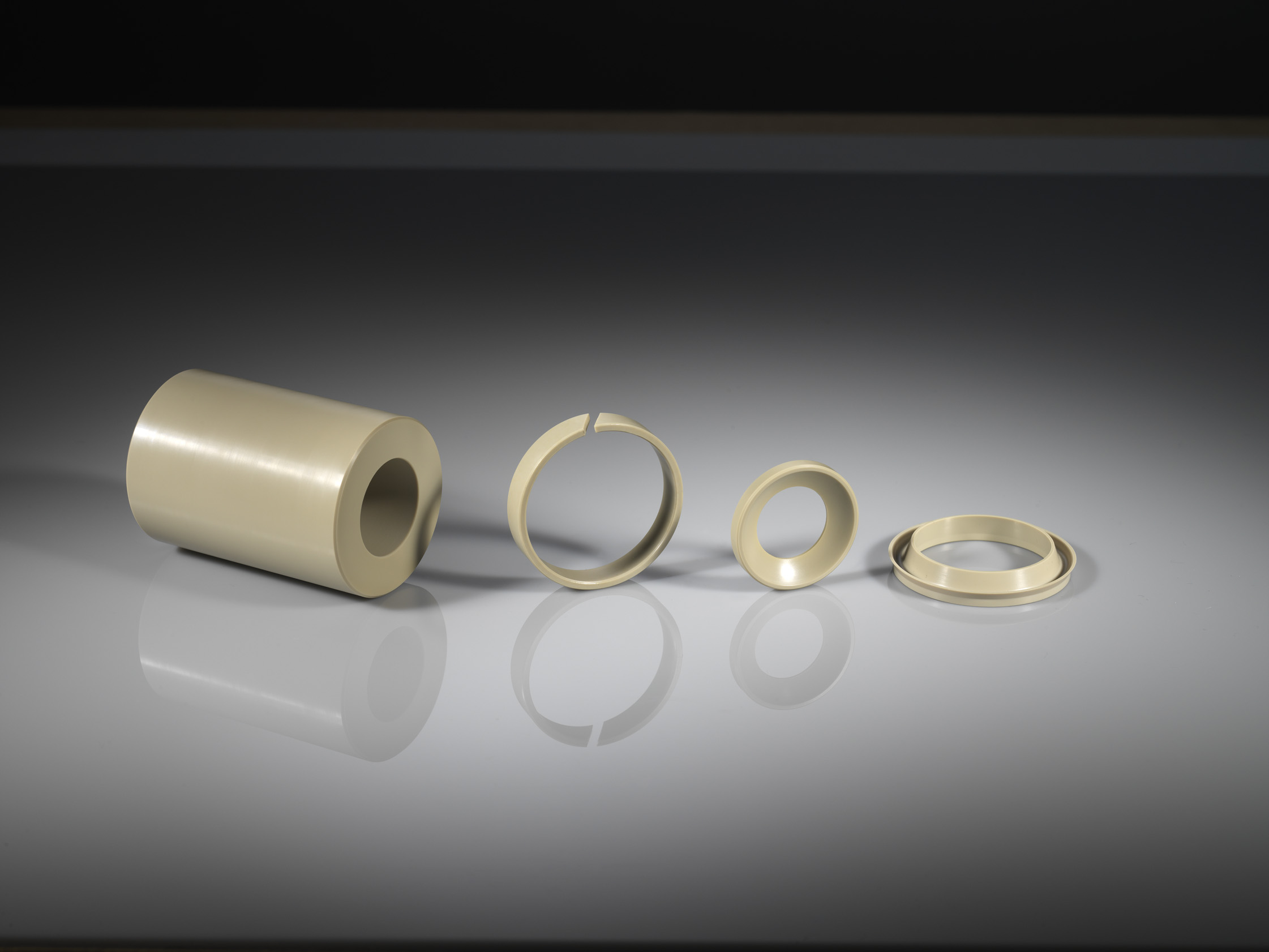

(PEEK / PEKK / VESPEL™)M Seals holds an extensive range of semi-finished advanced engineering plastic materials in stock to enable rapid turnaround of finished products to our customers.

Advanced engineering plastics advantages

Advanced engineering plastics such as PEEK, PEKK, PBI and others can offer many advantages over metallic materials when chosen correctly. They have excellent mechanical and thermal properties, while providing superior chemical and corrosion resistance.

Listed below are just a few of the advantages of using advanced engineering plastics in place of metallic components:

- Elimination of lubrication, enabling dry running

- Reduced wear on mating parts

- Reduced friction, providing faster operating speeds

- Lower torque values, resulting in reduced power consumption

- Improved corrosion and chemical resistance

- Compliance with industry specifications such as Norsok M-710

Choosing the correct material

When choosing the best advanced engineering plastic for your application, we must consider your application conditions, such as temperature, load, speed and chemical compatibility.

Refer to our material data sheets or contact us for more information.

Data sheet

Temperature

Hardness

Description

PKV-CRD86

Unreinforced Virgin PEEKMin: —

Max: +250°C88 Shore D A high-performance unreinforced virgin PEEK material with excellent thermal resistance, high compressive strength, low wear properties and low creep values.

PKV-CRD86-M710

Norsok Compliant Unreinforced Virgin PEEKMin: -50°C

Max: +260°C82 – 90 Shore D

A high-performance Norsok M710 compliant unreinforced virgin PEEK material with excellent thermal resistance, high compressive strength, low wear properties and low creep values.

Approvals: Norsok M-710 compliantPKFC30-BLK87

Carbon Fibre Filled PEEKMin: —

Max: +260°C89 – 91 Shore D

A high-performance carbon fibre reinforced PEEK material with excellent thermal resistance, high compressive strength, low wear properties and low creep values.

PKFC30-BLK87-API

Compliant Carbon Fibre Reinforced PEEKMin: —

Max: +260°C89 Shore D

A high-performance carbon fibre reinforced PEEK material with excellent thermal resistance, high compressive strength, low wear properties and low creep values.

Approvals: ISO 10423 Appendix F.1.13.5.2 (API 6A)PKBG30-BRM85

Reinforced Lubricated-PEEKMin: —

Max: +260°C85 Shore D

A modified PEEK which has been reinforced with fillers of carbon fibre and lubricants. This provides the material with excellent thermal resistance, higher compressive strength, lower wear properties and lower creep values.

PKFG30-CRD89

Glass Fibre Filled PEEKMin: —

Max: +260°C89 Shore D

A high-performance glass fibre reinforced PEEK material with excellent thermal resistance, high compressive strength, low wear properties and low creep values.

PKFG30-CRD89-M710

Norsok Compliant Glass Fibre Filled PEEKMin: —

Max: +260°C89 Shore D

A high-performance Norsok M710 compliant glass fibre reinforced PEEK material with excellent thermal resistance, high compressive strength, low wear properties and low creep values.

Approvals: Norsok M-710 compliantPKTFE-CRD84

PTFE Filled PEEKMin: -50°C

Max: +250°C78 Shore D

A high-performance PTFE lubricated PEEK material with excellent sliding ability, excellent thermal resistance, high compressive strength, low wear properties and good chemical resistance.

PKV-BLKD82

Black Pigmented Virgin PEEKMin: -50°C

Max: +250°C82 Shore D

A high-performance unreinforced virgin PEEK material that has been pigmented black in colour. It has excellent thermal resistance, high compressive strength, low wear properties and low creep values.

PKV-BLK83-M710

Black Norsok Compliant Unreinforced Virgin PEEKMin: -50°C

Max: +250°C80 – 85 Shore D

A high-performance Norsok M-710 compliant virgin PEEK material which has been modified with a black pigment. It has excellent thermal resistance, high compressive strength, low wear properties and low creep values.

Approvals: Norsok M-710 compliantPKGRF-BLKD85

Graphite Filled PEEKMin: -50°C

Max: +260°C85 Shore D

A high-performance graphite reinforced PEEK material that provides enhanced mechanical properties and reduced coefficient of friction values.

PKMT-BLKD85

Black Medical Technology MT Grade PEEKMin: -50°C

Max: +260°C85 Shore D

A high-performance black pigmented PEEK material that is suitable for medical applications and has excellent resistance to hydrolysis, superheated steam and is particularly useful for steam autoclaving.

PKHT-BLKD85

Black High Temp HT Grade PEKMin: -50°C

Max: +260°C85 Shore D

A high-performance black pigmented PEK material (commonly referred to as PEEK-HT or Victrex HT™) that is suitable for high temperature applications requiring increased compressive strength and wear resistance while under high thermal load.

PKST-BLKD86

Black High Temp ST Grade PEKEKKMin: -50°C

Max: +260°C85 Shore D

A high-performance black pigmented PEKEKK material (commonly referred to as PEEK-ST or Victrex ST™) that is suitable for high temperature applications requiring increased mechanical properties while under high thermal loads.

PPS-ND85

Unreinforced Virgin PPS PolyphenylensulfideMin: —

Max: +230°C85 Shore D

A high-performance unreinforced virgin PPS (Polyphenylensulfide) material that was developed to bridge the gap between general engineering plastics such as POM/Nylon and the more advanced engineering plastics such as PEEK.

PPS-GF-D88

Glass Reinforced PPS PolyphenylensulfideMin: —

Max: +230°C88 Shore D

A high-performance glass fibre reinforced PPS (Polyphenylensulfide) material that was developed to bridge the gap between general engineering plastics such as POM/Nylon and the more advanced engineering plastics such as PEEK.

Contact us

Please contact our technical team should you require any help choosing the correct material for your application or if the material you require is not shown.