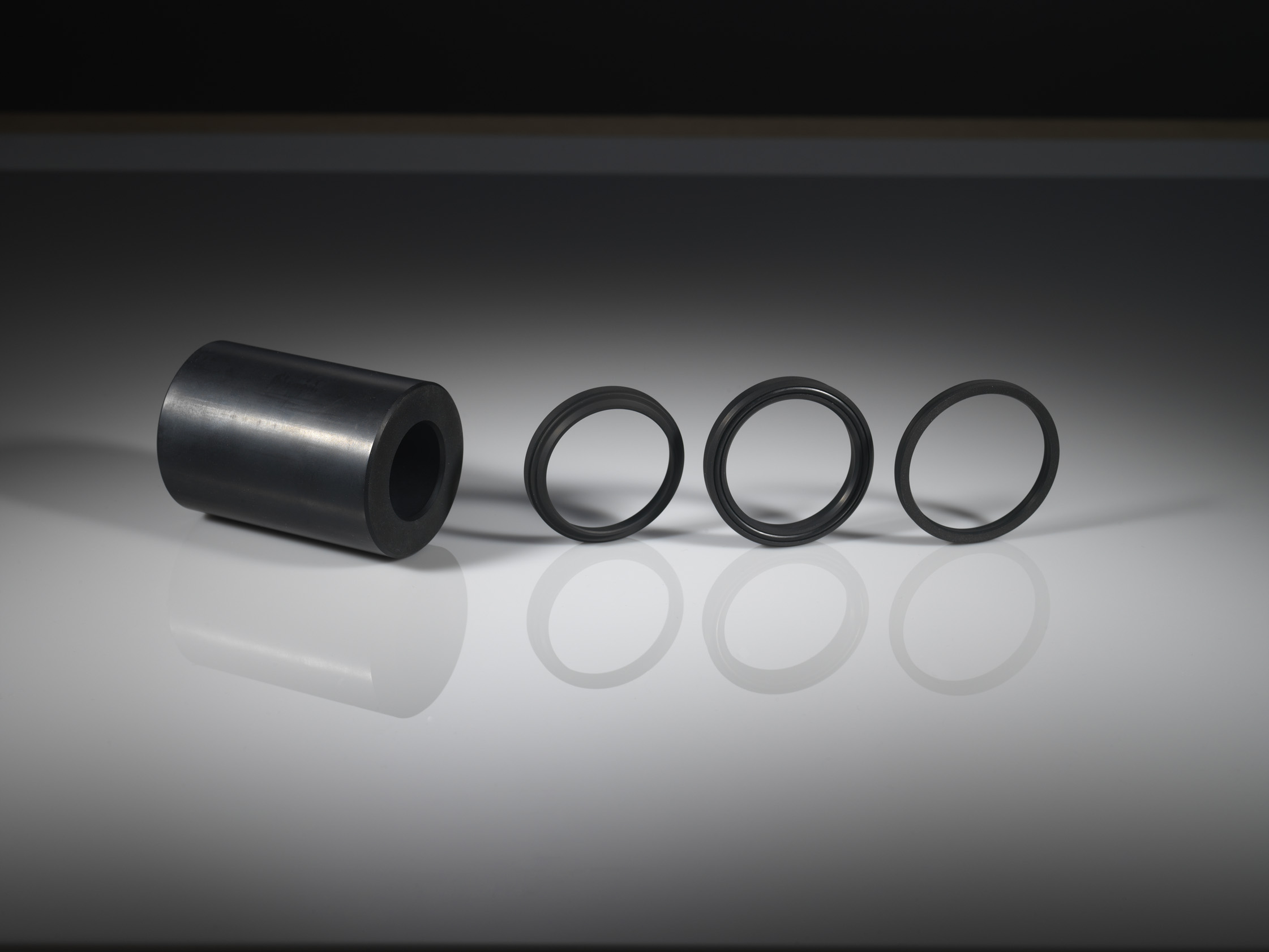

Carboxylated Nitrile Rubber (XNBR)

Carboxylated nitrile rubber (XNBR) compounds are formed by chemically modifying the polymer backbone of nitrile rubber by subjecting it to carboxylic acid groups during the polymerisation process. The addition of this process provides the compound with enhanced wear and abrasion resistance while also increasing modulus and tensile strength.

Carboxylated nitrile rubber (XNBR) compounds are usually utilised for wiper seals and O-ring energised U-cup seals working in dynamic service and/or applications which could be subjected to abrasive contaminants contained in the fluid or media, such as sand or scale.

Caution utilising carboxylated nitrile rubber

Caution should be taken when utilising XNBR compounds due to possible installation issues caused by the material being less flexible than standard nitrile rubbers because of the increased modulus of the material.

Data sheet

Temperature

Hardness

Description

XNBR-B90

Carboxylated Nitrile Rubber 90aMin: -30°C

Max: +100°C89 Shore A

Commonly referred to as XNBR or X-Nitrile. Has the addition of a Carboxyl group at the polymerisation stage of manufacture, which provides increased tear and abrasion resistance when compared to basic NBR.

Any questions?

If you have any questions about this material, or need help selecting the best seal and material for your application, please contact us.