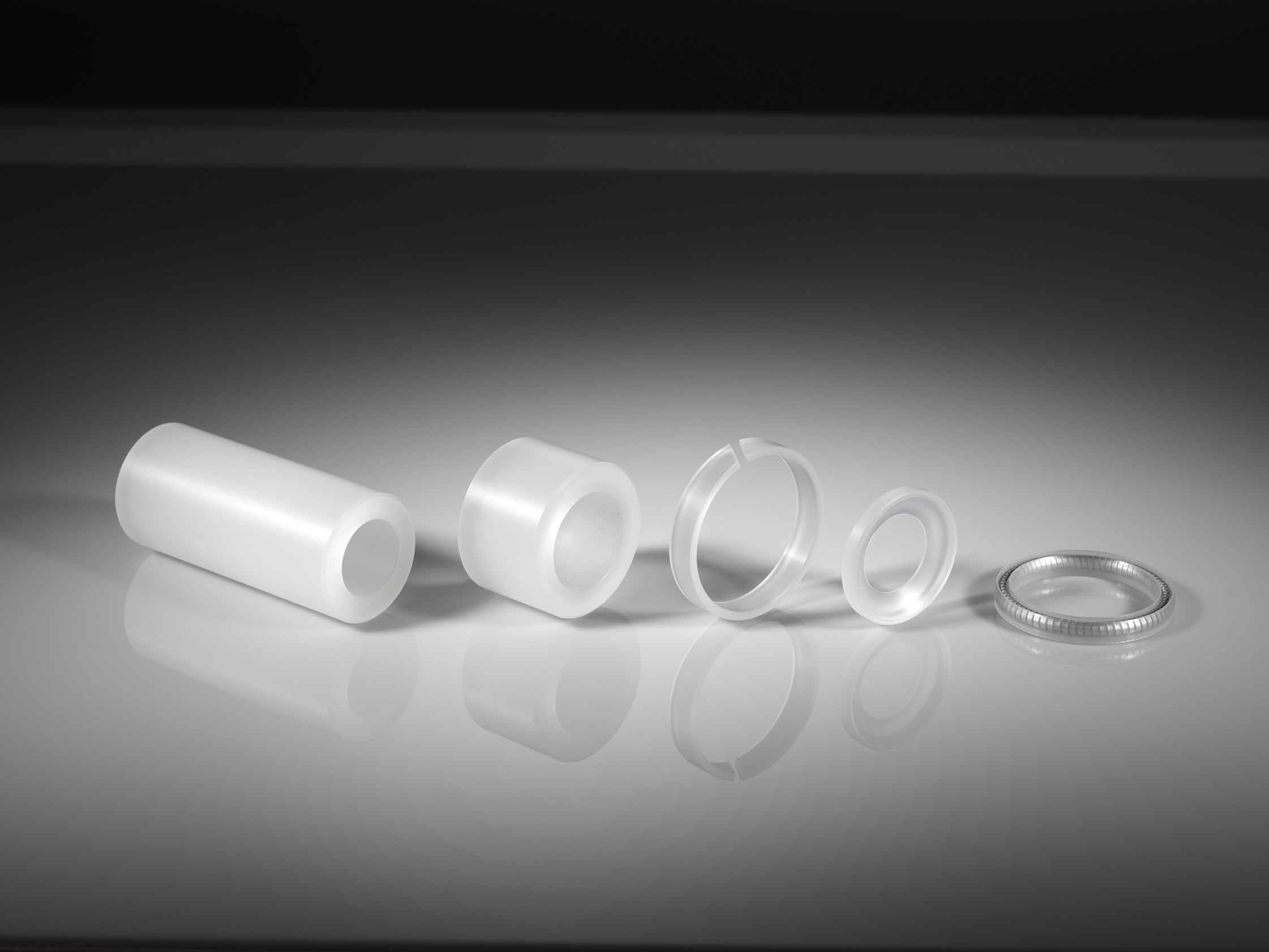

Fluoropolymers (PCTFE)

Fluoropolymers are high-performance plastics with strong carbon-fluorine bonds. This bond provides the compounds with excellent chemical resistance and good mechanical properties. They are an excellent choice for a multitude of uses including pharmaceutical, cryogenic, high-temperature and low friction applications, where their properties in these areas are unequalled.

Data sheet

Temperature

Hardness

Description

PCTFE

Thermoplastic ChlorofluoropolymerMin: -240°C

Max: +132°C90 Shore D

A thermoplastic chlorofluoropolymer, and commonly referred to as PCTFE or Kel-F®*. It has excellent chemical and permeation resistance and the lowest water vapor transmission rate of any plastic.

PVDF-CD72

Thermoplastic FluoropolymerMin: -60°C

Max: +150°C72 – 82 Shore D

A thermoplastic fluoropolymer produced via the polymerisation of Vinylidene Difluoride. It has superior creep resistance and is resistant to most solvents, acids and alkalis while having a low moisture uptake.

FEP-TD55

Fluorinated Ethylene Propylene FEPMin: -250°C

Max: +205°C55 – 60 Shore D

A melt processable semi crystalline fluoropolymer which is commonly referred to as FEP. The material has excellent temperature and chemical resistance properties with a better impact resistance than that of PTFE.

ETFE-D67

Ethylene Tetra Fluoro EthyleneMin: -100°C

Max: +150°C62 – 72 Shore D

A fluorine based plastic specifically designed to provide increased corrosion and strength resistance over a wide temperature range. It has excellent resistance to ultra-violet light and high energy radiation.

PFA-OD63

PerFluoroAlkoxy PFAMin: -200°C

Max: +250°C60 – 65 Shore D

A copolymer of TetraFluoroEthylene and Perfluoroethers specifically designed to provide corrosion, creep resistance and thermal resistance close to that of PTFE.

ECTFE

Ethylene ChlorotrifluoroethyleneMin: -75°C

Max: +150°C70 – 80 Shore D

Excellent dimensional stability and mechanical properties; stiffer and stronger than many of the other types of fluoropolymer materials. Has a low coefficient of thermal expansion and very low moisture absorption.

Talk to us

We can help you choose the correct fluoropolymer for your application. Please contact our technical department for assistance.