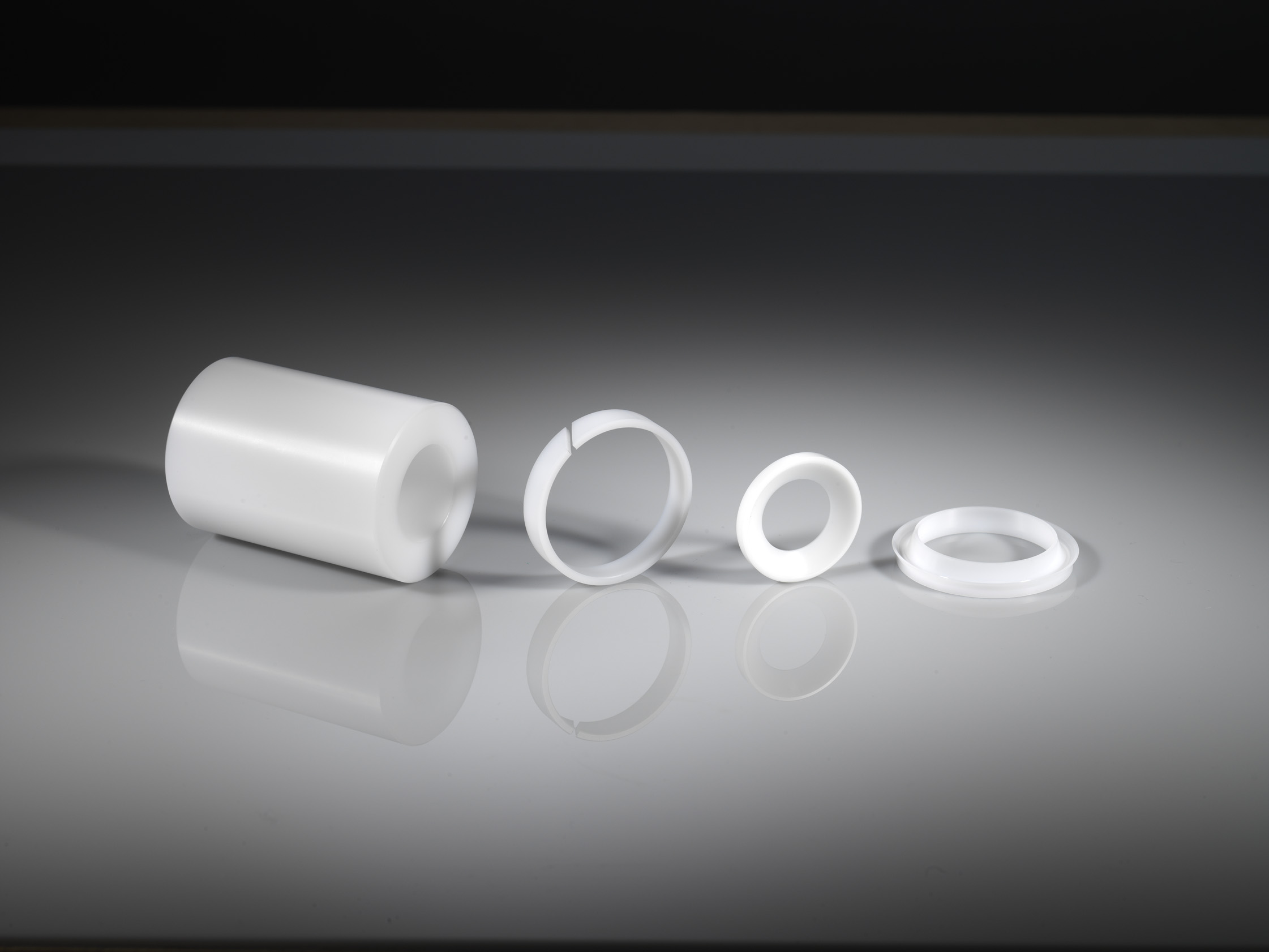

General Engineering Plastics

(POM / PA / PE)M Seals holds an extensive range of semi-finished general engineering plastic materials in stock to enable rapid turnaround of finished products to our customers.

General engineering plastics such as Polyacetal (POM), Polyamide (PA, Nylon) and others can offer many advantages over metallic materials when chosen correctly:

- Reduction in weight

- Reduced cost

- Excellent wear properties

- Thermal insulation

Choosing the correct general engineering plastic

When choosing the best general engineering plastic for your application, we must consider your application conditions, such as temperature, load, speed and chemical compatibility.

Refer to our material data sheets or contact us for more information.

Data sheet

Temperature

Hardness

Description

POMC-WD83

Polyacetal CopolymerMin: -50°C

Max: +100°C83 Shore D

Commonly referred to as POM, TAL or Acetal, with high mechanical strength, rigidity, excellent wear resistance and good sliding properties.

POMC-BD85

Black Polyacetal CopolymerMin: -50°C

Max: +100°C85 Shore D

Commonly referred to as POM, TAL or Acetal, with high mechanical strength, rigidity, excellent wear resistance and good sliding properties.

PA6-ND83

Nylon 6Min: -40°C

Max: +100°C83 Shore D

Commonly referred to as Nylon 6, PA6 or Polyamide 6, with high mechanical, flexural and compressive strength, good rigidity and excellent wear resistance.

PA6-BD83

Black Nylon 6Min: -40°C

Max: +100°C83 Shore D

Commonly referred to as Nylon 6, PA6 or Polyamide 6, with high mechanical, flexural and compressive strength, good rigidity and excellent wear resistance.

PA6M

MoS2 Filled Nylon 6Min: -40°C

Max: +105°C80 Shore D

Modified by the inclusion of an internal MoS2 filler to provide lower friction values, better sliding properties and lower water absorption.

PA66

Nylon 66Min: -30°C

Max: +100°C82 Shore D

A very rugged material that offers good heat and chemical resistance while also providing good abrasion resistance.

PA66M

MoS2 Filled Nylon66Min: -30°C

Max: +100°C82 Shore D

An engineering thermoplastic which has been modified by the inclusion of an internal MoS2 filler to provide lower friction values and better sliding properties in comparison to the standard unfilled grade.

PA6L-GD82

Green Oil Filled Lubricated Nylon 6Min: -40°C

Max: +110°C82 Shore D

Modified by the inclusion of an internal lubrication system to provide lower friction values, better sliding properties and lower water absorption in comparison to the standard unfilled grade.

PA6L-RD83

Red Self Lubricating NylonMin: -40°C

Max: +110°C83 Shore D

Modified by the inclusion of an internal lubrication system to provide lower friction values, better sliding properties and lower water absorption in comparison to the standard unfilled grade.

PA11-BD83

Nylon 11Min: -50°C

Max: +85°C83 Shore D

Commonly referred to as Nylon 11, Polyamide11 or PA11. This material has good mechanical properties in the areas of tensile strain, wear resistance and compressive strength.

PET-WD87

White Natural Polyethylene Terephthalate ErtalyteMin: -20°C

Max: +110°C87 Shore D

A crystalline unreinforced engineering thermoplastic polyester (PET) which has high mechanical strength, good sliding properties, excellent rigidity and wear resistance.

PPC-ND69

Polypropylene CoPolymerMin: -30°C

Max: +100°C69 Shore D

An amorphous polypropylene co-polymer which provides high heat resistance, strength, toughness and chemical corrosion resistance.

HDPE-ND63

High Density PolyethyleneMin: -50°C

Max: +80°C63 Shore D

Commonly referred to as PE300, HDPE or PEHD. Good chemical resistance, low coefficient of friction, excellent wear resistance and very low moisture absorption.

UHM-WD60

Natural Ultra High Molecular Weight PolyethyleneMin: -200°C

Max: +80°C60 Shore DA very tough material, with extremely high impact strength, excellent resistance to corrosive chemicals, excellent low-temperature characteristics and a coefficient of friction.

UHM-GD60

Green Ultra High Molecular Weight PolyethyleneMin: -200°C

Max: +80°C60 Shore DA tough material, with extremely high impact strength, excellent resistance to corrosive chemicals, excellent low-temperature characteristics and a coefficient of friction.

Contact us

Please contact our technical team should you require any help choosing the correct material for your application.