How Custom Sealing Solutions Can Solve Complex Engineering Challenges

In the world of modern engineering, success often hinges on the smallest components. Seals play a vital role in ensuring the safety, efficiency, and longevity of complex systems. Yet, in many advanced applications, off-the-shelf seals simply don’t cut it. That’s where custom sealing solutions come into play.

Across a range of industries, custom sealing systems are becoming indispensable tools for engineers tackling unique design and performance challenges.

Let’s take a look at how and why they make a difference…

The Custom Sealing Advantage

Custom sealing solutions are tailored to meet specific functional, environmental, and regulatory needs.

Custom-made for your specific needs

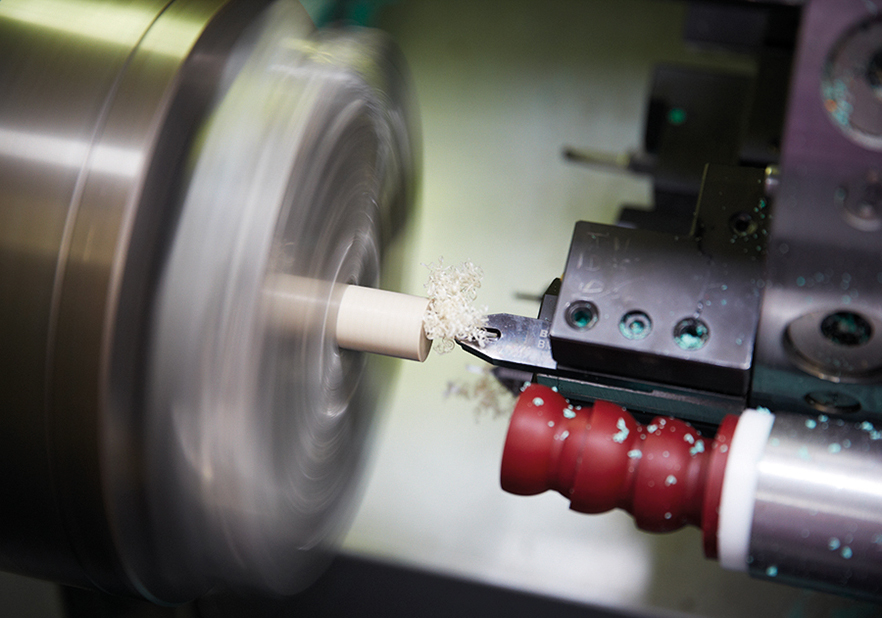

As the name suggests, custom seals are designed and manufactured by expert engineers to meet the exact requirements of your unique application. Bespoke engineered seals take into account specific conditions like speed, temperature, application, media, pressure and surface, to ensure a perfect match. Custom seals are designed to integrate seamlessly into complex machinery, reducing the chance of leaks and mechanical wear.Bespoke design support

Custom seal design can help to solve a variety of complex sealing challenges where standard seals are not suitable. Challenges may include the need for non-standard seal dimensions, unusual shapes, integration with intricate machine designs, or specialised applications. Design support can include custom CAD seal design, application engineering support, material recommendations, research and development for seal improvement, correct installation and tool design guidance and product reference drawings.Seal material selection

Bespoke seals will often use advanced or specialist materials that are not typically used for standard seals. Advanced materials will be selected based on the application’s needs, where products may need to withstand high temperatures and pressures, aggressive chemicals, radiation or UV exposure or sterilisation cycles in medical equipment. The correct choice of material is not only vital for safety and efficiency, but also for enhancing the seal’s durability and functionality.Cost effective

Whilst bespoke seals may mean a higher initial investment, they are more cost effective over time as their tailored design and durability mean less frequent maintenance and fewer replacements. A correctly designed and fitted, high-quality seal can offer sustained performance and efficiency, minimising machinery downtime and loss of productivity.Enhanced performance and durability

By optimising the shape, profile, and material of the seal, engineers can minimise friction, improve longevity, and reduce maintenance needs. This is critical in industries where failure is not an option - such as aerospace, oil & gas, or semiconductors.Support for innovation

Custom sealing solutions empower innovation. When companies develop new technologies, standard parts may not exist yet. Seal manufacturers who offer custom engineering can collaborate directly with design teams, enabling faster prototyping and validation.Regulatory and industry compliance

Many industries, such as food & beverage, pharmaceutical and aerospace, demand adherence to strict standards. Custom seals can be developed to meet various industry requirements and standards, ensuring both safety and compliance.Bespoke Seals Solving Real-World Challenges

We have a range of case studies across the many industries we work within, showing how bespoke seals have solved varying challenges. Here are snippets of just a couple:

Spring Energised Seals for Cryogenic Quick Connect / Disconnect Coupler

A world leading coupling manufacturer was designing a new type of QCDC coupler and was having continuous issues with the main seal. Having already tried many manufacturers and sample seals with little or no success and being almost ready to scrap the project and write-off hundreds of thousands of pounds, they contacted M Seals to see we could find a solution.

After assessment of the challenges, we designed and manufactured a bespoke spring energised seal. The combination of a special high-load spring energiser and fluoropolymer seal jacket was proposed to enable the seal to provide leak-tight performance and resist shrinkage while performing at cryogenic temperatures. Seals were supplied quickly (3 days after initial assessment) and successfully passed all tests.

A customer required large diameter rotary shaft seals for a Hydropower Unit, which were designed and manufactured within just one week, compared to the usual 6-week lead time for standard rotary shaft seals. An increase in water pressure meant a recommendation for a double-acting solid PTFE rotary lip seal (RB31), which could handle significantly higher pressures. It also meant that only one seal was required, due to its dual sealing lips. Within one week, the hydropower station resumed operation and continued producing green electricity.

Collaboration = Success

The process of developing a custom seal isn’t just about specifying dimensions. It’s a collaborative effort between sealing solution experts and customers. By sharing as much application data as possible, the best solution can be co-created to produce reliable and efficient seals.Custom sealing solutions aren’t a workaround; they’re a strategic asset in modern engineering. When performance, reliability, and safety are on the line, investing in the right seal can be the key to overcoming even the most complex design challenges.

If your project demands more than a standard solution, consider partnering with a sealing expert who can solve complex sealing challenges.

As we say – small things make great things possible.