Preventing Leaks, Improving Performance: How O-Rings Optimise Automotive Systems

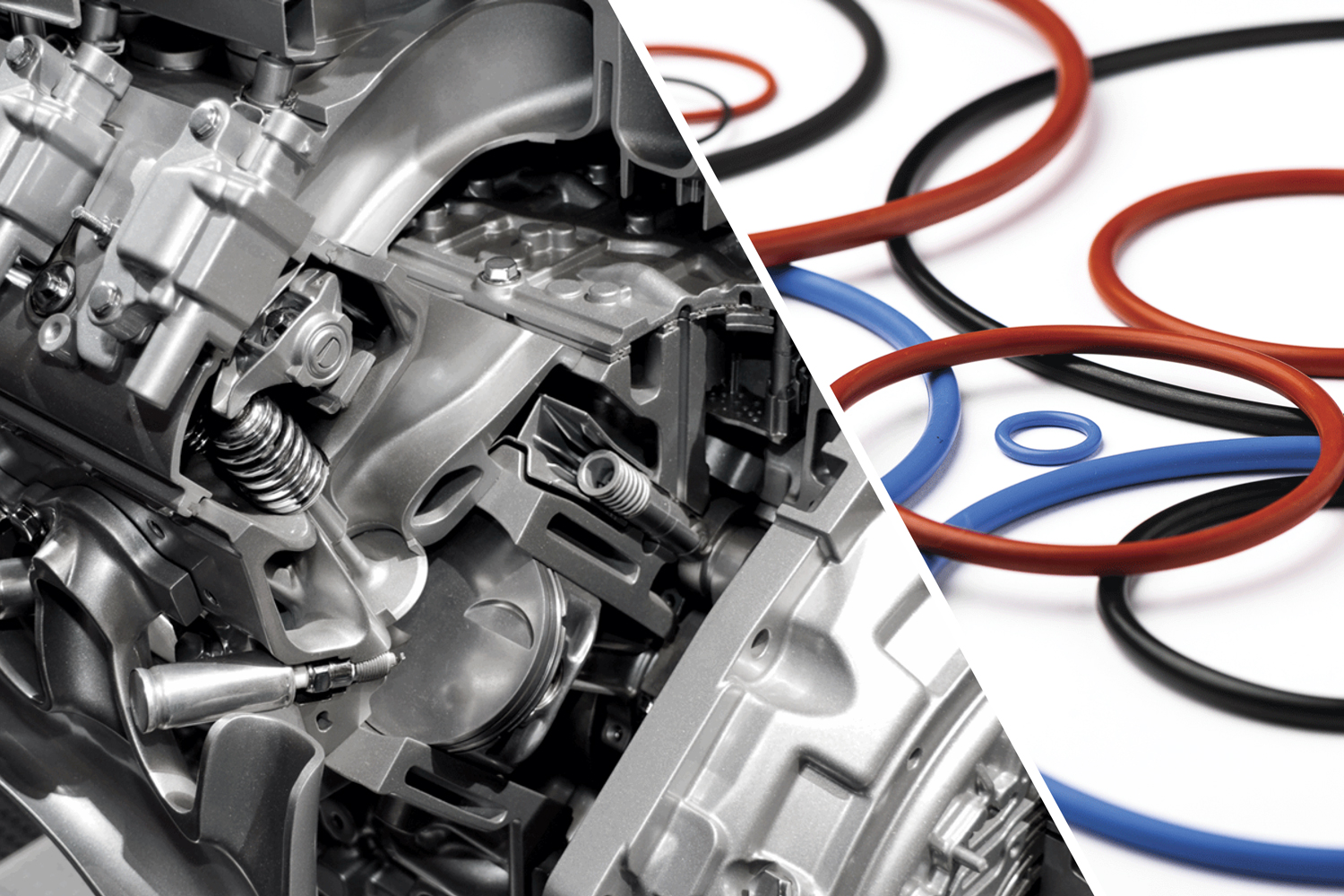

When it comes to automotive performance, most drivers think about horsepower, fuel economy, or technology features. But hidden under the bonnet, are small, precision-engineered components that make all those things possible. One of these is the o-ring.

O-rings play a critical role in preventing leaks, maintaining pressure and ensuring the reliable function of virtually every system in a modern vehicle.

They are essential components in every type of vehicle – whether it’s a reliable everyday car, a rugged off-road truck, or a high-performance Formula 1 race car. From sealing oil systems to managing high-pressure fuel and hydraulic circuits, o-rings ensure reliability, safety, and efficiency across all levels of automotive engineering.

Read on to find out how o-rings optimise automotive systems and support overall vehicle performance.

Where O-Rings Make an Impact in Automotive Systems

Engine Sealing

O-rings are essential in sealing oil systems, coolant passages and internal engine components. They prevent leaks in:

- Oil pumps and oil filters

- Water pumps and coolant outlets

- Cylinder head covers

Proper sealing in these areas ensures the engine remains well-lubricated and cool – directly impacting performance, fuel economy, and engine longevity.

Fuel System Efficiency

In high-pressure fuel injection systems, even the smallest leak can result in a drop in performance or a safety hazard. O-rings help maintain a leakproof seal in:

- Fuel injectors

- Fuel rails

- Fuel pumps

They also help contain emissions and maintain fuel pressure for optimal combustion.

Transmission Reliability

Automatic and manual transmissions rely on hydraulic pressure to shift gears smoothly. O-rings are used in:

- Valve bodies

- Transmission pumps

- Solenoid assemblies

A failed o-ring here could cause slippage, overheating or total transmission failure.

Brake and Power Steering Systems

Brake systems operate under high pressure. O-rings are used in:

- Master cylinders

- Caliper pistons

- ABS control units

Similarly, in hydraulic power steering, o-rings help maintain fluid pressure and prevent leaks that could reduce steering response or cause component wear.

Air Conditioning and HVAC

O-rings keep refrigerant and lubricants sealed inside A/C systems, ensuring cooling performance and system longevity. They must resist both high and low temperatures, as well as aggressive refrigerants.

How do O-Rings Improve Automotive Performance?

O-rings don’t just prevent leaks, they actively support performance by:

- Maintaining system pressure: Essential in fuel, braking and transmission systems

- Reducing friction and wear: By keeping lubricants where they belong

- Improving thermal management: Ensuring coolants flow properly

- Extending service intervals: Thanks to improved durability and material resistance

- Enhancing safety and compliance: Preventing leaks that could lead to fire hazards or environmental violations

Choosing the Right O-Ring Material

O-ring performance varies greatly depending on its material, which should be carefully chosen based on the fluid, pressure and temperature range of the application.

Common options in the automotive industry include:

- NBR (Nitrile): Ideal for oil, fuel, and general applications

- HNBR: Excellent resistance to heat, oils, fuels, and chemicals and good mechanical properties

- FKM (Viton®): High resistance to heat, fuel, and chemicals

- EPDM: Suitable for brake fluid and coolant systems

- Silicone: Great for temperature extremes and electrical sealing

To determine the best o-ring material to optimise your automotive systems, feel free to speak to our experts.

Why Quality O-Rings Matter

A single failed o-ring can cause significant issues:

- Fluid leaks and system failure

- Reduced performance and efficiency

- Costly repairs or warranty claims

- Customer dissatisfaction

That’s why investing in high-quality o-rings is a proactive step toward preventing downtime, enhancing vehicle reliability, and protecting your brand reputation.

In summary…

In automotive engineering, performance isn’t just about power – it’s about precision. O-rings may be small, but their impact cannot be ignored. From sealing fluids to supporting advanced vehicle systems, they’re an integral part of the performance equation.

Small things make GREAT things possible

If you need help improving system reliability or solving a persistent sealing issue to meet tough automotive demands, please feel free to contact our experts.