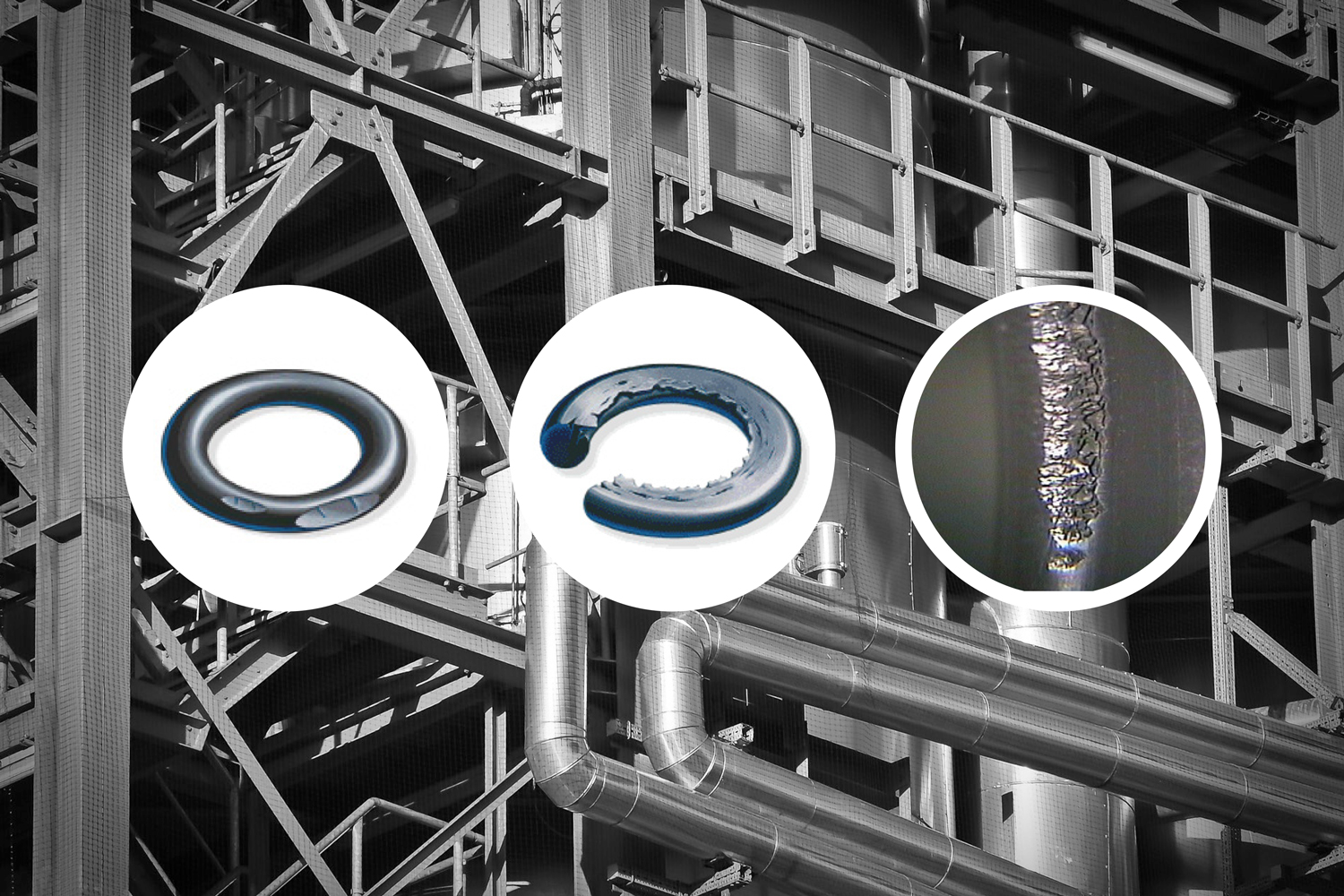

Top Causes of Seal Failure and How to Prevent Them

In the world of industrial machinery and engineering, seals may seem like small components, but their importance is significant. They keep systems running smoothly, prevent leakage, maintain pressure and protect against contamination. When a seal fails, it can lead to costly downtime, safety risks and expensive repairs.

Understanding the critical role seals play in your operations is essential, so read on to find out the most common causes of seal failure and, more importantly, how you can prevent them.

Improper Installation

One of the most common reasons for premature seal failure is improper installation. Overstretching, incorrect orientation, or using the wrong tools can damage the seal before it even goes into service.

Prevention Tips:

- Train maintenance staff on correct installation procedures.

- Use the proper tools and lubrication during installation.

- Always follow manufacturer guidelines for fitting and orientation.

Incorrect Seal Selection

Using a seal not designed for your specific operating conditions (temperature, pressure, speed or chemical exposure) can lead to early degradation.

Prevention Tips:

- Work with a sealing solutions expert to choose the right material and design for your application.

- Evaluate operating conditions (e.g., temperature range, fluid compatibility, system pressure) carefully before selection.

Material Incompatibility

Seals made from incompatible materials can swell, shrink, crack or degrade when exposed to certain chemicals or temperatures.

Prevention Tips:

- Know your fluid media and environmental conditions.

- Choose seal materials that are chemically and thermally compatible with your system.

- Consult chemical resistance charts or work with an experienced manufacturer or supplier for expert advice.

Excessive Wear and Friction

Continuous operation, high-speed environments or abrasive materials can cause seals to wear out faster.

Prevention Tips:

- Use seals with low-friction coatings or designs that reduce heat buildup.

- Schedule regular maintenance to inspect and replace worn seals.

- Consider upgrading to high-performance materials in demanding applications.

Thermal Degradation

Exposure to extreme heat can harden, crack or melt seals, especially if they’re not designed to handle such conditions.

Prevention Tips:

- Select seals rated for the actual temperature ranges of your application.

- Ensure proper heat dissipation in equipment design.

- Monitor system temperature to catch overheating early.

Pressure-Related Failures (Extrusion or Blowout)

High system pressures can cause seals to extrude into gaps or blow out of their grooves if the design is not pressure-optimised.

Prevention Tips:

- Use back-up rings or anti-extrusion devices in high-pressure applications.

- Confirm that seals meet pressure specifications for your system.

- Inspect gland design and tolerances for proper fit.

Contamination and Foreign Particles

Dirt, dust, metal shavings or other contaminants can erode seal surfaces or become embedded, causing leakage and premature wear.

Prevention Tips:

- Install filters and dust covers where possible.

- Maintain clean assembly and operating environments.

- Regularly inspect and clean equipment.

Aging and Environmental Exposure

Over time, UV light, ozone and oxygen exposure can degrade seal materials, especially in outdoor or static applications.

Prevention Tips:

- Use UV- and ozone-resistant materials for exposed applications.

- Store seals in cool, dark, and dry environments.

- Replace seals periodically, even if not in active service.

In Summary…

Seal failure is rarely due to a single cause – it’s often a combination of factors. By understanding these common failure modes and implementing proactive prevention strategies, you can extend the life of your seals, reduce unplanned downtime, and protect your equipment investment.

If you find yourself with a troublesome sealing issue or are designing a new system and want to get the small things right from the beginning, our team is always on hand to help if you are looking for expert advice. Contact us today to speak with one of our sealing specialists.