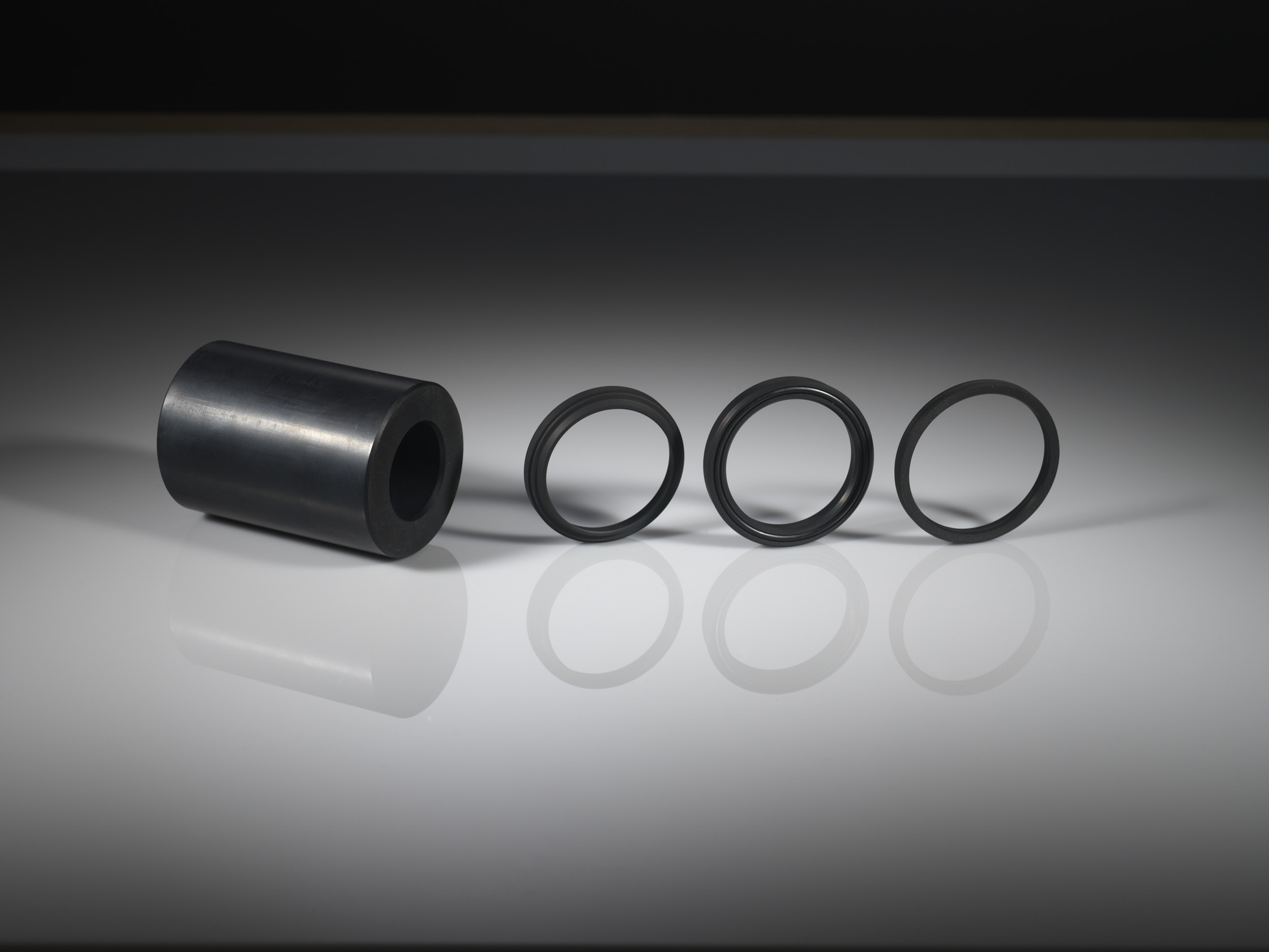

Hydrogenated Nitrile Rubber

(HNBR / HSN)Hydrogenated Nitrile Butadiene Rubber (HNBR), also referred to as Highly Saturated Nitrile (HSN) is a modified class of Nitrile rubber where the polymer chain has been saturated with hydrogen atoms (hydrogenated) to provide the material with superior mechanical and physical properties in comparison to standard Nitrile (NBR).

HNBR resistance

HNBR materials offer superior heat and chemical resistance against standard NBR grades. Like NBR, the variations in the Acrylonitrile (ACN) content determine the material's resistance to oils and solvents, while the degree of hydrogen saturation influences the heat resistance of the compound. A lower ACN content will provide improved low temperature flexibility, but will affect the compound's chemical resistance.

HNBR materials bridge the gap between Nitrile (NBR) and Fluorocarbon (FKM / FPM / Viton™) rubbers in areas where the resistance to aggressive fluids / media and temperature resistance are required simultaneously. HNBR is generally a lower cost alternative to fluorocarbon rubber materials.

We have a number of high performance HNBR materials available to suit a wide range of applications.

Data sheet

Temperature

Hardness

Description

HNBR-B85

Standard Grade Peroxide Cured HNBRMin: -25°C

Max: +150°C83 Shore A

A peroxide cured Hydrogenated-Acrylonitrile-Butadiene-Rubber (HNBR / HSN) which has excellent abrasion resistance, good compression set resistance and offers a wide temperature range.

HNBR-B90

Hard Grade Hydrogenated Nitrile 90aMin: -20°C

Max: +150°C90 Shore A

Our hard grade HNBR / H-NBR / HSN which has excellent abrasion and extrusion resistance, and also offers a wide temperature range.

HNBR-B95

Extreme Hard Grade Hydrogenated Nitrile 95a HNBRMin: -20°C

Max: +150°C95 Shore A

Our extreme hard grade HNBR / H-NBR / HSN, which has excellent abrasion and extrusion resistance, which makes it a good choice for high pressure applications.

HNBR-B75

75a Shore Nitrile RubberMin: -20°C

Max: +150°C75 Shore A

A soft HNBR / H-NBR / HSN, which provides good temperature resistance, excellent elasticity and compression-set characteristics.

HNBR-FQ-G82

Green FDA Compliant HNBRMin: -30°C

Max: +150°C82 Shore A

An FDA compliant HNBR material, with improved chemical resistance over standard nitrile compounds. HNBR-EDB85

Explosive Decompression ED Resistant HNBRMin: -15°C

Max: +150°C85 Shore A

A peroxide cured HNBR / H-NBR / HSN which has been optimised and tested against Norsok M-710 requirements for resistance to Explosive Decompression (ED).

HNBR-LT-RGDB85

Low Temp RGD Resistant Peroxide Cured HNBRMin: -40°C

Max: +150°C83 Shore A

Optimised for resistance to the risk of Rapid Gas Decompression (RGD) and to allow its use in low temperature applications.

Approvals: RGD (Rapid Gas Decompression) resistanceHNBR-G85

Green Commercial Grade HNBRMin: -25°C

Max: +150°C85 Shore A A green coloured commercial grade HNBR / H-NBR / HSN, which has excellent abrasion, tear resistance and chemical resistance.

HNBR-RGDB90

Norsok M-710 & API6A Compliant Peroxide Cured HNBRMin: -20°C

Max: +150°C83 Shore A

Approvals: ISO 23936-2 / Norsok M-710 Annex A & B compliant & ISO 10423:2009 F.1.13.5.2 API 6A FF/HH tested & RGD (Rapid Gas Decompression) resistance Technical Help

Please contact our technical team if you require further information or cannot find the material compound you require.