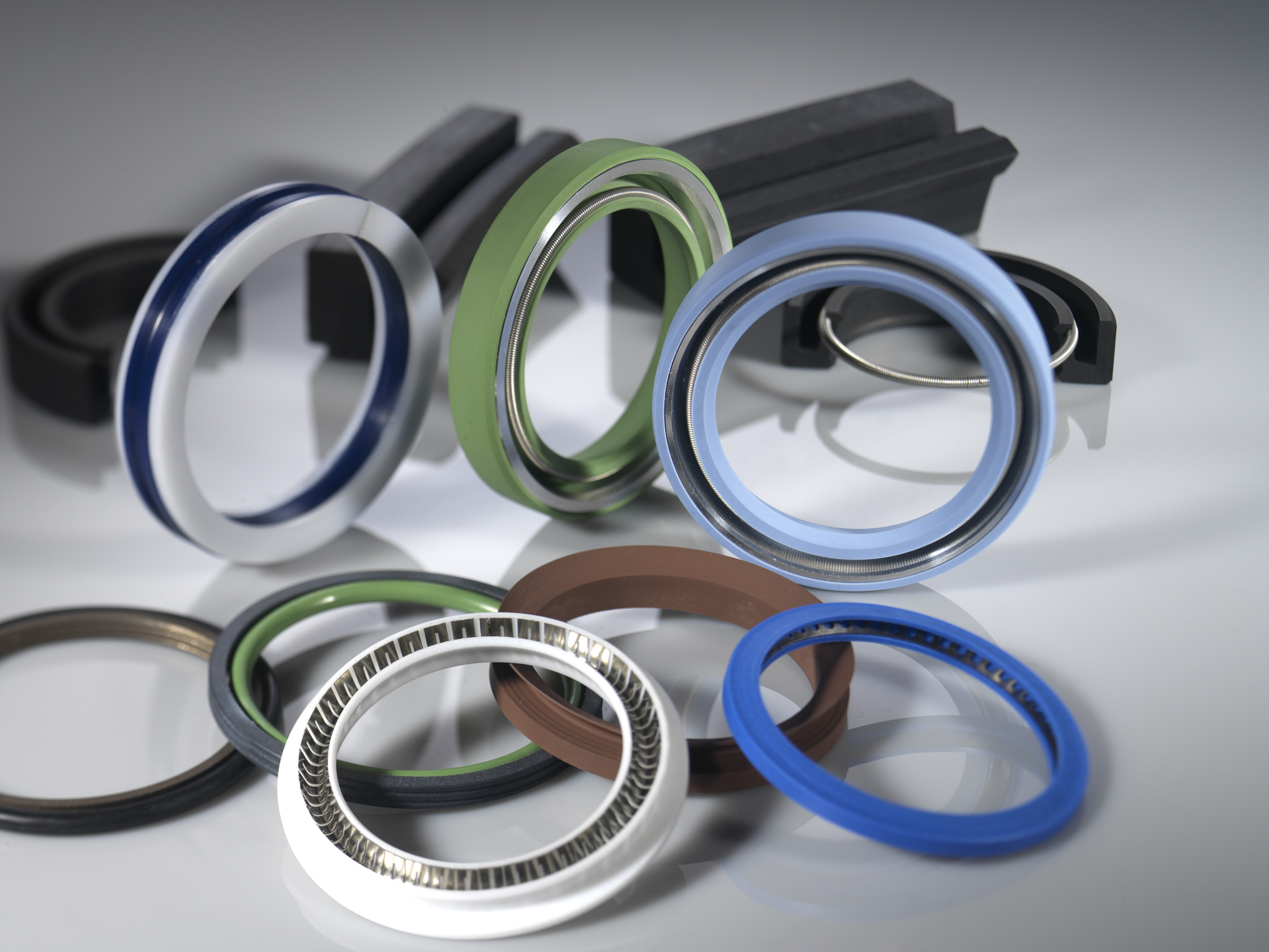

Rotary Shaft Seals

Rotary seals, also known as lip seals, are a vital component in machinery used across numerous industries. These seals are responsible for ensuring that fluids do not leak, whilst also protecting the internal components from dust, dirt and other contaminants.

Types of rotary shaft seals

There are different types of rotary shaft seals, each with its own specific design and materials. Some common types include:

Radial Lip Seals

Also known as lip seals or shaft seals, they are the most common type of rotary seal. They are typically used in applications where the sealing surface is rotating relative to the housing. Radial lip seals can be designed for low to high-speed applications and are available in a variety of materials to suit different fluid and temperature requirements.V-Ring Seals

V-rings are another type of rotary seal that are used for shafts that rotate in both directions. They are typically made of elastomer or rubber and can handle high-speed applications. V-ring seals are effective at preventing contamination from entering the shaft area.Mechanical Seals

Designed to seal against the rotating shaft using two flat surfaces, they are typically used in high-pressure applications where a high degree of sealing is required. Mechanical seals can be made from a variety of materials including ceramic, carbon and metal.Labyrinth Seals

Labyrinth seals are a non-contact type of rotary seal that use a series of grooves to create a tortuous path for the fluid or gas to flow through. They are typically used in high-speed applications where there is a risk of fluid leakage. Labyrinth seals are effective at preventing contamination from entering the shaft area.Gland Seals

Gland seals are typically used to seal a rotating shaft, where the shaft passes through a stationary housing or casing, such as in a pump or a mixer. The packing material used in gland seals can be made of various materials such as graphite, PTFE, aramid fibre or carbon.Applications of rotary seals

Rotary shaft seals are designed to withstand pressures up to 20 bar and temperatures up to 260°C (depending on material and composition), making them an ideal solution for highly varied conditions in applications such as:

Pumps: Rotary seals are used in pumps to prevent leakage of fluids such as water, oil and chemicals.

Compressors: Rotary seals are used to prevent leakage of gases such as air, natural gas and refrigerants.

Gearboxes: Used in gearboxes to prevent leakage of lubricants such as oil or grease.

Motors: Prevent leakage of coolant or lubricant fluids.

Marine Applications: Used in marine applications such as propeller shafts, rudder shafts and thrusters to prevent leakage of seawater.

Automotive Applications: Used in automotive applications such as wheel bearings, differential gears and engine crankshafts to prevent leakage of oil and other fluids.

Food and Beverage Industry: Rotary seals are used to prevent contamination and ensure hygiene standards.

Pharmaceutical Industry: Used to prevent contamination and ensure product integrity.

Choosing the right rotary shaft sealChoosing the right rotary shaft seal is essential for ensuring the proper functioning of machinery. Several factors can affect the performance of rotary shaft seals, including:

- Temperature: The operating temperature of machinery can affect the performance and longevity of rotary shaft seals, so choosing the right seal material is crucial.

- Pressure: The pressure of the fluid being sealed can also affect the performance of rotary shaft seals, so it is essential that the seal chosen can withstand the pressure.

- Speed: The speed at which the shaft is rotating can affect the performance of rotary shaft seals, so it is important to choose a seal that is designed for the appropriate speed range.

- Fluid type: The type of fluid being sealed can also affect the choice of rotary shaft seal. Different fluids have different chemical properties that can affect the performance of the seal.

Benefits of using rotary shaft seals

Prevent fluid leakage: Rotary shaft seals prevent fluids from leaking out of machinery, reducing the risk of damage to internal components, and avoiding downtime for repairs.

Reduce maintenance costs: By preventing fluid leakage and reducing wear and tear on internal components, rotary shaft seals can help reduce maintenance costs over time.

Increase efficiency: Using the right rotary shaft seal can help minimise friction and wear on internal components, improving efficiency and reducing energy consumption.