PTFE Seals

PTFE seals (polytetrafluoroethylene seals) are widely recognised for their exceptional performance, durability, and chemical resistance in demanding industrial applications.

We offer a comprehensive range of high-performance static and dynamic PTFE sealing solutions, engineered to withstand extreme mechanical stress and aggressive chemical environments—conditions where conventional sealing materials often fail.

Manufactured using advanced processing techniques, our PTFE seals deliver outstanding versatility and long-term reliability. They are available in standard sizes or can be custom-designed to fit specific applications and existing housings, often without additional tooling costs.

PTFE seals are commonly used across a wide range of industries, including chemical processing, food and pharmaceutical manufacturing, petrochemical operations, offshore applications, and hydraulic systems, where reliable sealing performance is critical.

Properties of PFTE seals

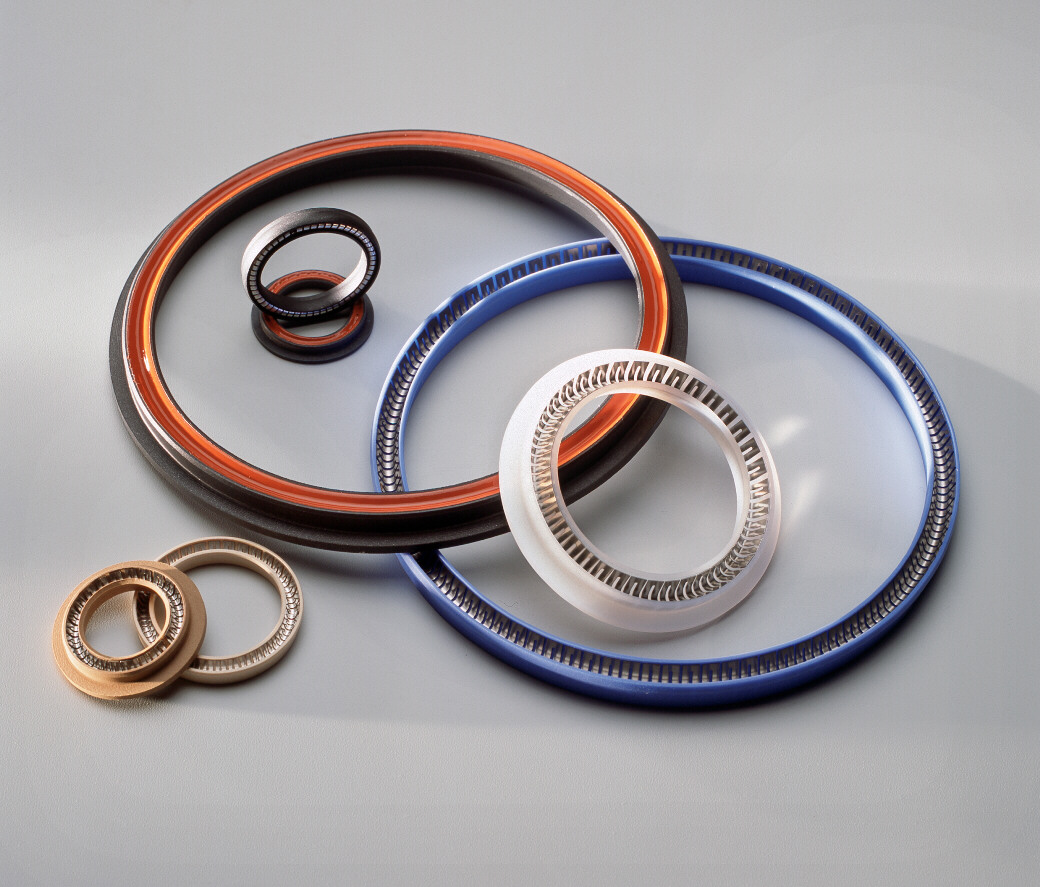

PTFE is a relatively inelastic material. To secure surface contact prior to system pressure, a PTFE seal must be equipped with an elastic element. This can be either a stainless-steel spring (Fig. 1) or an elastomer O-ring (Fig. 2).

Fig. 1

Fig. 2Each application determines whether one or the other is the most optimal type, often based upon working temperature or demand of chemical resistance.

Advantages of PTFE seals

- Resistant to a large number of chemicals and do not react with the fluid.

- Can be used within a wide temperature range, (-200° to +260°C) with considerations to the design.

- Good wear property and the elastic elements’ low setting, secure a long service life.

- Has unlimited stock life, but considerations must be taken to lifetime of an eventual elastomer element.

- Has extremely low friction and does not bond to the contact surface.

- High resistance to extrusion.

- High surface speeds can be obtained up to 15m/s reciprocating and 4m/s for rotating.

Chemical resistance

PTFE seals are widely acclaimed for their exceptional chemical resistance; enabling them to maintain their integrity and sealing performance against:

- Acids (including strong mineral acids such as hydrochloric acid, sulfuric acid, nitric acid and hydrofluoric acid)

- Alkali Solutions (including caustic substances such as sodium hydroxide and potassium hydroxide)

- Solvents (including acetone, ethanol, methanol and toluene)

- Corrosive Gas (such as chlorine, ammonia, hydrogen chloride and sulphur dioxide)

- Oxidation

It is important to note that while PTFE seals offer exceptional chemical resistance, their performance may vary depending on the specific chemical, concentration, temperature and duration of exposure. We always recommended that you contact us for specific chemical compatibility data and recommendations tailored to the intended application.

Temperature rangePTFE seals offer outstanding temperature resistance; they perform reliably from -200°C (-328°F) in cryogenic conditions to 260°C (500°F) in high-temperature environments. This makes them suitable for industries ranging from aerospace and medical to automotive and chemical processing. Actual operating limits may vary based on fillers and design; please consult our technical team for more information.

PTFE material composition and fillers

PTFE (polytetrafluoroethylene) can be combined with various fillers to enhance its properties and performance:

- Glass Fibre: Increases strength, dimensional stability and load-bearing capacity.

- Carbon (fibres or graphite): Improves thermal conductivity, wear resistance and high-temperature performance.

- Bronze or MoS₂: Provides self-lubrication, reduces friction and extends seal life.

- Ekonol (PolyEtherKetone): Enhances wear resistance and stability under extreme temperatures.

These fillers allow PTFE seals to be tailored for specific applications, optimising strength, thermal performance, lubricity and durability.

Custom Manufactured PTFE Seals

When standard PTFE seals are not suitable, M Seals can design and manufacture bespoke engineered solutions for specific applications.

Read more about our Machined PTFE Seals.