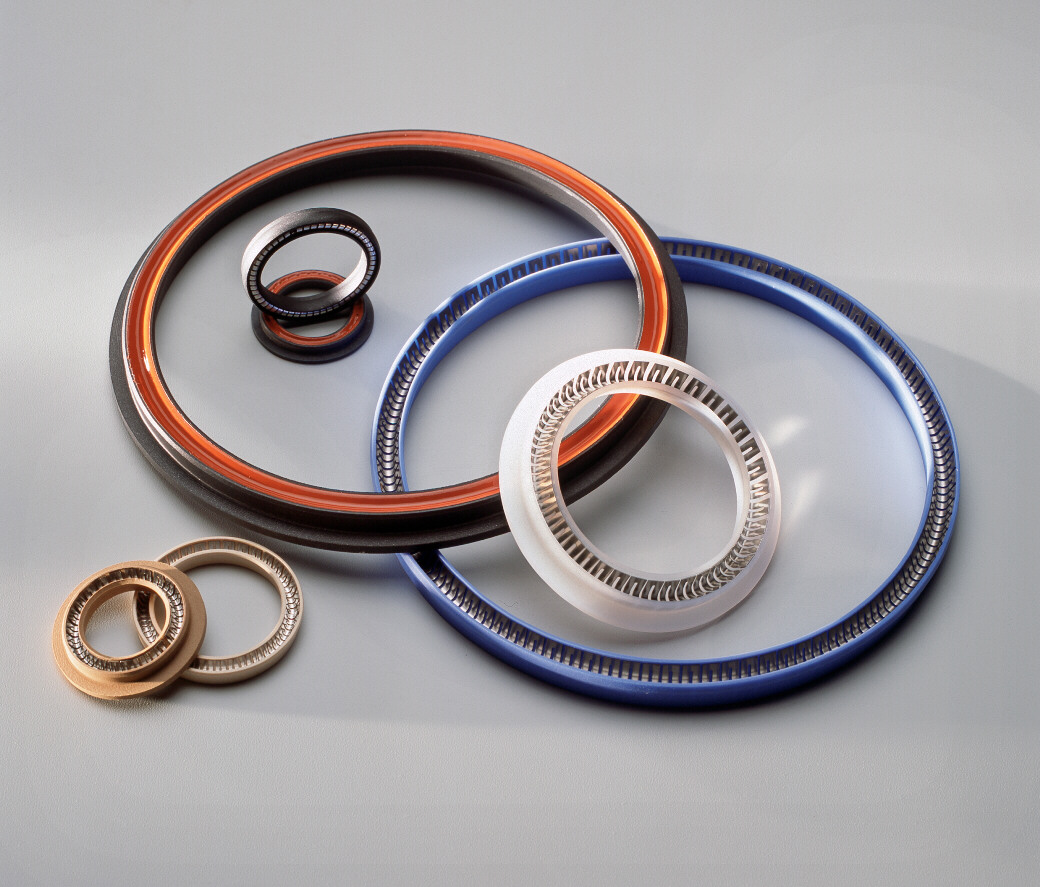

M-Flex®

M-Flex® are single acting, spring-energised seals, effective in a wide range of dynamic and static applications.

M-Flex® spring-energised seals are chosen when higher resistance to chemical media is required, where the seal is required to operate in extremes temperatures and where good extrusion and compression characteristics are needed.

Characteristics of M-Flex®

- Resistant to a large number of chemicals and do not react with the fluid.

- Reliable within a wide temperature range, (-269° to +280°C) with considerations to the design.

- Good wear property and the elastic elements’ low setting, secures a long service life.

- Unlimited stock life, but considerations must be taken to lifetime of an eventual elastomer element.

- Extremely low friction and does not bond to the contact surface.

- High resistance to extrusion.

- High surface speeds can be obtained up to 15m/s reciprocating and 4m/s for rotating

M-Flex® Profiles

Profile

Name

Operating range

Summary

RB19 Pressure Max: 150 bar

Temperature Min: -200 °C Max: 260 °C

Speed Max: 2 m/sRB19 is a spring energized PTFE rotary seal with clamping flange. Seal cannot rotate with the housing due to oversize flange thickness between clamping plates. Stainless steel spring ensures sealing at low pressures is achieved. FDA compliant version available.

ESF3 Pressure Max: 400 bar

Temperature Min: -200°C Max: 260°C

Speed Max: 15 m/sESF3 is a symmetrical single acting U-Cup spring energised seal and

Is designed for use in static, dynamic reciprocating and rotary applications involving hardware with large gland tolerances or where misalignment issues are present.The ESF series of seal are the correct choice for friction critical applications due to the flat load this spring energiser exhibits.

The seal consists of a U-shaped jacket and elliptical coiled spring which is manufactured from round wire and formed into a slanted shape. The spring is available in three different spring loads to control load and friction, these consist of light, medium and heavy sections. Medium load is always the starting point for any new application.

USF2 Pressure Max: 500 bar

Temperature Min: -200 °C Max: 260 °C

Speed Max: 15 m/sUSF2 seal is primarily intended for dynamic applications where reciprocating or slow rotating movement is present.

The seal consists of a U-shaped jacket with radiused sealing faces for good low friction operation and a cantilever U-Shaped spring which offers moderate load versus deflection which is suitable for most applications.

The design of the cantilever spring places the spring load at the front of the sealing lip making the CSE series an excellent option should a scraper lip be required for abrasive media sealing.

Download CatalogueCatalogue

Summary

DownloadDownload the PTFE Sealing system catalogue for detailed information about materials, assembly instructions and standard dimensions lists.