M-Turn®

M-Turn® seals are used as a double acting O-ring activated rotary seal for hydraulic and pneumatic equipment in sectors such as:

- Rotary distributors and unions

- High pressure valve stems

- Manipulators

- Pivoting motors in mobile hydraulics and machine tools

- Hydraulic motors

- Blow moulding machines

- Top drives

- Rotary tables

- Swivels

- Core cutting equipment

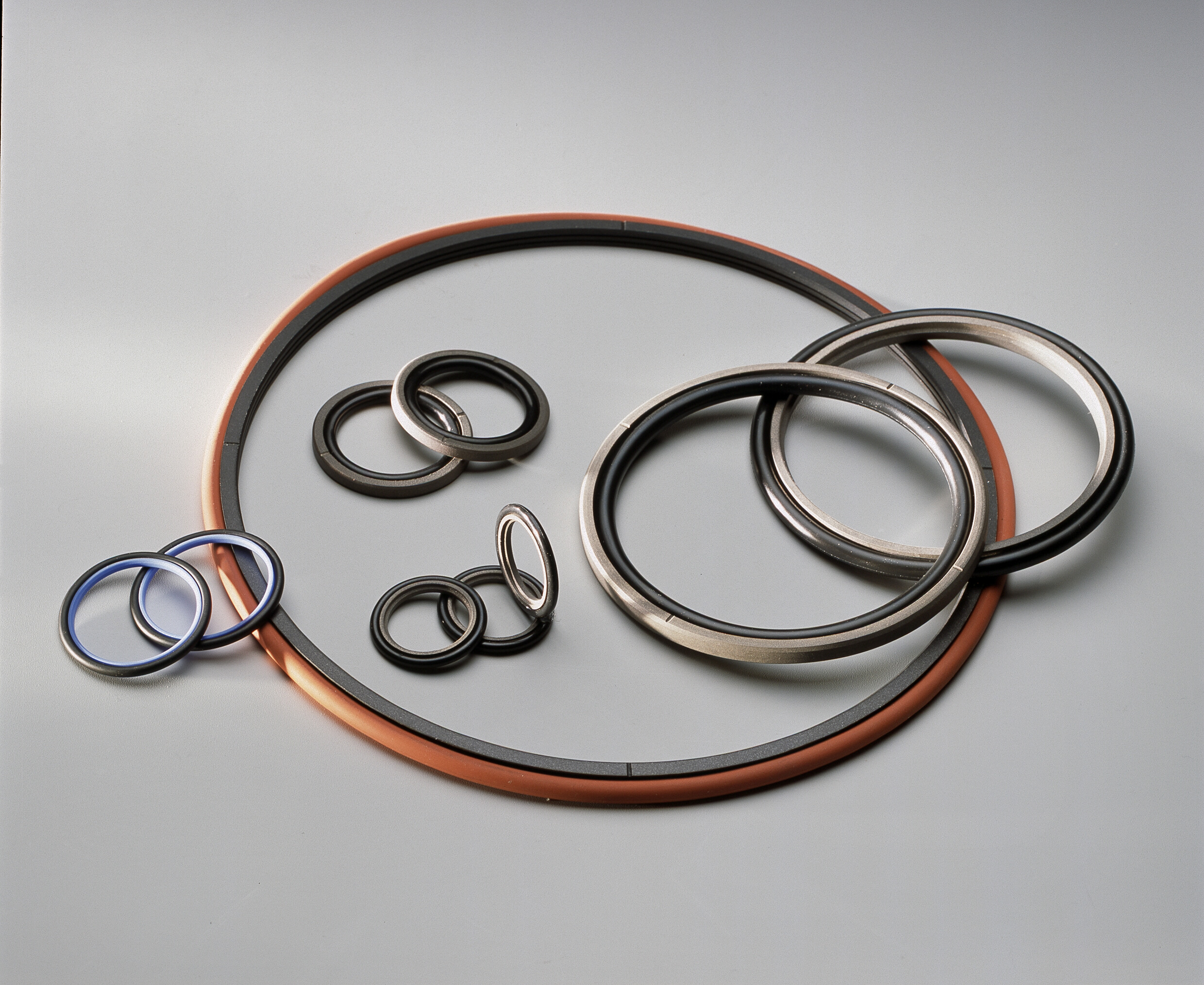

M-Turn® has a compact design suitable for small installation spaces where a low friction seal is required. It has excellent chemical and thermal resistance depending on O-ring material selection and is available in a wide range of PTFE compounds.

Characteristics of M-Turn®

The most important characteristics of the O-ring activated PTFE seal designs are:

- Double-acting seal

- Low friction

- Lubricant reservoir

- Stick-slip free operation

- No vulcanising to mating surfaces

- Simple groove design

- Small groove dimensions

- For use at high-pressure and low sliding-speeds

M-Turn® profilesProfile

Name

Operating range

Summary

RB10 Pressure Max: 300 bar

Temperature Min: -50 °C Max: 210 °C

Speed Max: 2 m/sPTFE composite rotating piston seal, o ring activated. Compact design suitable for small installation spaces where a low friction seal is required. Wide chemical and thermal resistance depending on o ring material selection. Wide range of PTFE compounds. Download catalogue

Catalogue

Summary

DownloadDownload the PTFE Sealing system catalogue for detailed information about materials, assembly instructions and standard dimensions lists.