V-Rings

V-rings are specialised sealing devices used to prevent the entry of dirt, dust and other contaminants into machinery or equipment. They are also designed to keep lubricants and other fluids from leaking out of the equipment. Due to their effectiveness and versatility, V-rings are commonly used in hydraulic and pneumatic systems, as well as in rotating shafts and gearboxes.

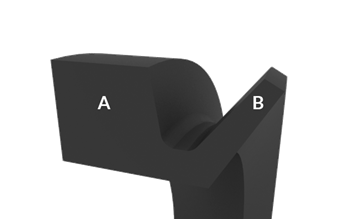

V-rings are fully moulded rubber seals with a unique V-shaped cross-section that is directly mounted on a shaft. The V-ring is designed to hold onto the shaft with its own radial elastic force and seal axially against a surface, effectively preventing the penetration of water, oil and other media.

Composed of two parts, the V-ring body (a) and the flexible, self-tightening sealing lip (b), V-rings can seal even with larger misalignments and eccentricities. This makes V-rings a reliable and cost-effective sealing solution for a wide range of applications.

V-ring specifications

V-rings are available in a range of diameters to suit various applications. The size range typically starts from as small as 3mm in diameter and can go up to several thousand millimetres.

They are often used in conjunction with other sealing solutions to provide optimal sealing performance. For example, they can be used in combination with radial shaft seals to improve the overall sealing effectiveness of a system. When selecting V-rings and other sealing solutions, it is important to consider factors such as operating conditions, media compatibility and the required level of sealing performance.

What are the benefits of using V-rings?

One of the main benefits of using V-rings is that they are highly effective at preventing contamination and leakage. This can help to extend the lifespan of equipment and reduce maintenance costs.

V-rings are also highly versatile and suitable for use in a wide range of applications. They can be used in both dynamic and static sealing applications and can accommodate a variety of shaft sizes and materials. This versatility makes them a cost-effective and practical solution for many different industries.

Another benefit of V-rings, is their high durability, making them long-lasting, even in harsh operating conditions. They are designed to withstand high temperatures, high pressures and exposure to chemicals and other corrosive substances. This durability helps to reduce the need for frequent replacement and maintenance, which can save time and money in the long run.

V-rings are also easy to install and replace, which makes them a convenient solution for equipment manufacturers and maintenance technicians. They do not require any special tools or equipment for installation and can be easily removed and replaced when necessary.

Finally, V-rings are environmentally friendly and do not contain any harmful substances. They are made from non-toxic materials that are safe for use in a variety of applications, and they do not release any pollutants or contaminants into the environment.

Whether you are in the automotive, aerospace, or industrial sector, V-rings can provide reliable sealing performance and help to extend the lifespan of your equipment.

V-ring profile typesV-rings are available in four standard types (shown below). Each of these profiles has a unique design and is suitable for specific sealing applications.

Type VA is the most common profile and is available for shaft diameters starting from 2.7 mm up to almost unlimited sizes. It has a versatile design and is suitable for a wide range of applications. It provides good sealing properties and can handle misalignments and eccentricities.

Type VS provides a stronger radial hold on the shaft but requires more space due to its wider cross-section. It is available for shaft diameters ranging from 4.5 mm to 210 mm. It is suitable for applications where a stronger hold on the shaft is required.

Type VL is designed for applications where space is limited. It has a thinner cross-section than the other profiles, allowing it to fit in tight spaces. It is available for shaft diameters ranging from 135 mm to 630 mm.

Type VE is designed for heavy-duty applications where a large diameter seal is required to exclude dirt and water. It is suitable for applications such as paper mills, rolling mills, and other applications with large axial movements. It is available for shaft diameters ranging from 450 mm to 2000 mm and can be supplied with an additional radial retaining band for better fixation.

How to choose the right V-ring for your applicationThe choice of material for V-rings depends on several factors, including the specific application requirements and operating conditions. Here are some general guidelines for when to use different materials:

- Nitrile Rubber (NBR): Commonly used in V-rings due to its excellent resistance to oils and fuels. NBR V-rings are a good choice for applications in the automotive, agricultural and industrial sectors where exposure to oils and fuels is common. NBR V-rings can also withstand moderate temperatures and pressures, making them a versatile sealing solution.

- Chloroprene Rubber (CR): A type of synthetic rubber that offers good resistance to ozone and weathering, as well as moderate resistance to oils and chemicals. CR V-rings are commonly used in outdoor applications or equipment that is exposed to sunlight or weathering.

- Hydrogenated Nitrile Butadiene Rubber (HNBR): This material offers excellent resistance to chemicals, oils and high temperatures. HNBR V-rings are commonly used in automotive, industrial and oil and gas applications where exposure to harsh chemicals, fuels and high temperatures is a concern. HNBR V-rings can withstand temperatures up to 300°F (150°C) and offer good resistance to abrasion and wear.

- Fluoroelastomer (FKM) V-rings: These materials are a good choice for applications where high temperatures or exposure to harsh chemicals and fuels are present. FKM V-rings offer excellent resistance to chemicals and high temperatures, and are commonly used in aerospace, automotive and oil and gas applications.

- Ethylene Propylene Diene Monomer (EPDM) V-rings: A good choice for applications where exposure to ozone or weathering is a concern. EPDM V-rings offer excellent resistance to weathering and UV radiation, making them a good choice for outdoor applications or equipment that is exposed to sunlight.

- Polytetrafluoroethylene (PTFE) V-rings: These materials are a good choice for applications where extreme temperatures, high pressures, or exposure to harsh chemicals are present. PTFE V-rings offer excellent chemical resistance and low friction properties and can withstand temperatures up to 500°F (260°C). They are commonly used in chemical processing, food and beverage, and pharmaceutical applications.

- Metal V-rings: A good choice for applications where high temperatures, pressures, or abrasion resistance are required. Stainless steel or other metal alloys are commonly used for V-rings in hydraulic and pneumatic systems, as well as in rotary equipment and gearboxes.

- M Seals RADIAL OIL SEALS, HEAVY DUTY SHAFT SEALS, V RINGS 005028 Vers.615.7 MB