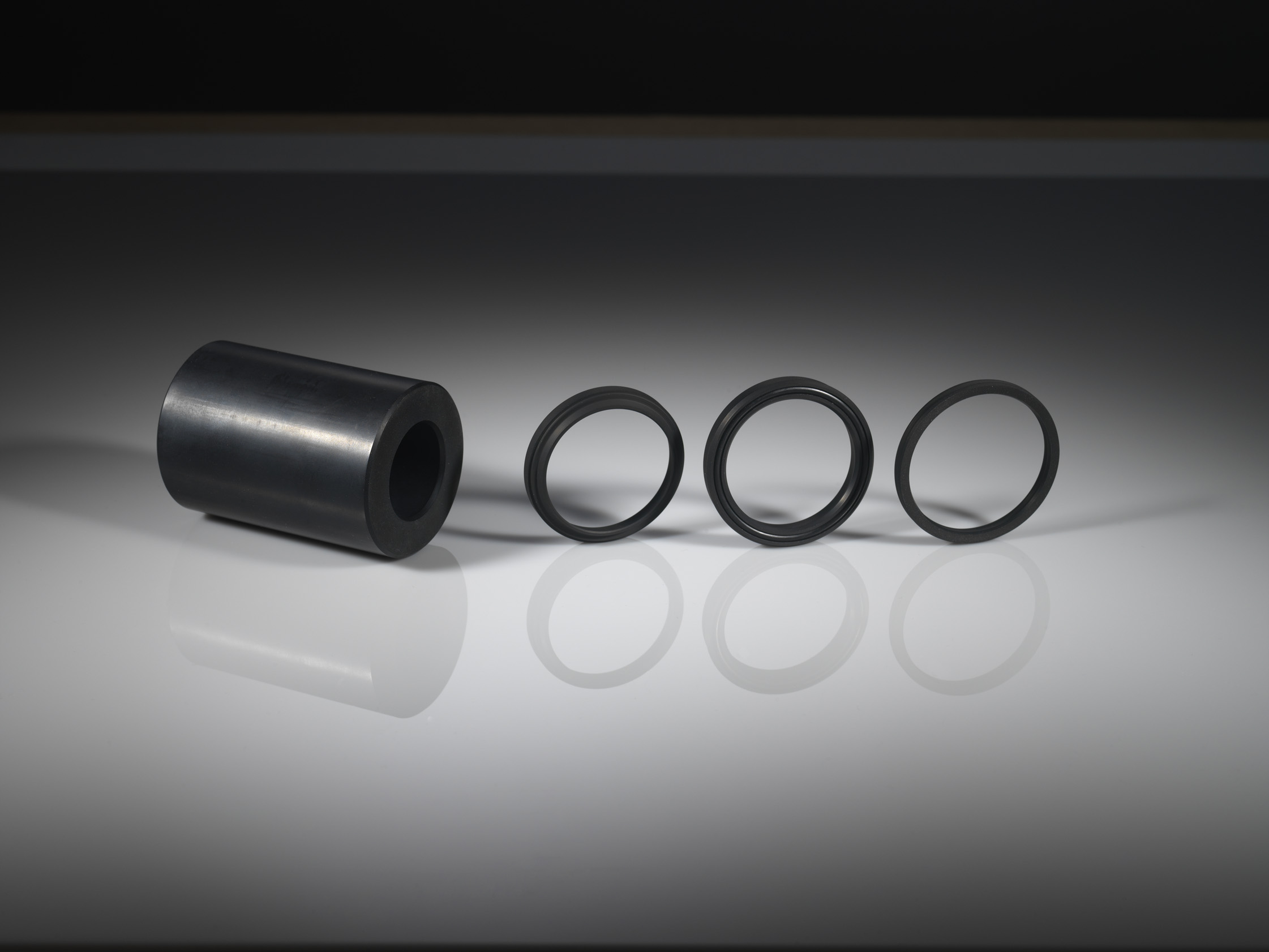

Perfluoroelastomers (FFKM / Kalrez™)

Perfluoroelastomer (FFKM) compounds are a ground breaking group of highly fluorinated elastomer materials which offer the chemical resistance and thermal properties of thermoplastic PTFE (Teflon®), while also offering the flexibility and resilience of an elastomer. FFKM offers the widest chemical resistance and temperature resistance of any elastomer, and can therefore be likened to a rubberised form of PTFE.

FFKM has an exceptional ability to resist wide temperature ranges and offers unparalleled chemical resistance against any other elastomeric material. It offers excellent resistance to permanent deformation and some grades offer high temperature resistance up to +330°C and low temperature flexibility at -45°C.

Within our wide range of Perfluoroelastomer materials, we have options to suit most applications, including material grades which offer Rapid Gas Decompression (RGD) resistance, Norsok M-710 approval and others which are FDA and USP Class IV approved.

Caution using Perfluoroelastomers (FFKM)

Caution should be taken when using FFKM in high temperature, high pressure environments, as the material will act as highly viscous fluid while under pressure and require an additional anti-extrusion / back-up ring to prevent extrusion and premature failure of the seal.

FFKM also has a higher coefficient of thermal expansion than other elastomer materials and cannot normally utilise standard O-ring groove designs. In normal room temperature conditions, the groove should be increased in volume - 25% more than the seal - to prevent extrusion caused by overfilling of the groove under thermal expansion.

Data sheet

Temperature

Hardness

Description

ZC005

Universal Grade FFKMMin: -15°C

Max: +260°C77 IRHD Developed to meet severe service requirements where application conditions may involve high temperature use and/or sealing of aggressive media.

ZC010

RGD Resistant FFKMMin: -15°C

Max: +260°C92 IRHD Developed to meet service requirements where application conditions may involve high temperature use and/or sealing of high pressure gas.

Approvals: RGD (Rapid Gas Decompression) resistanceZC100

White FDA Compliant PerfluorolastomerMin: -15°C

Max: +260°C77 IRHD Developed to meet severe service requirements where application conditions may involve high temperature use and/or sealing of aggressive media.

Approvals: FDAZC101

Black FDA Compliant PerfluorolastomerMin: -15°C

Max: +260°C77 IRHD Developed to meet severe service requirements where application conditions may involve high temperature use and/or sealing of aggressive media.

Approvals: FDAZC200

High Temperature FFKMMin: -15°C

Max: +300°C78 IRHD Developed to meet severe service requirements where application conditions may involve high temperature use and/or sealing of water and steam. ZC318

Ultra High Temp FFKMMin: -10°C

Max: +330°C75 Shore A A high performance perfluoroelastomer material that has superb thermal resistance characteristics coupled with broad chemical resistance.

ZC400

Hot Water Steam AED Resistant FFKMMin: -15°C

Max: +300°C92 IRHD Developed to meet severe service requirements where application conditions may involve high temperature use and/or sealing of water and steam.

ZC401

High Temperature FFKM Water SteamMin: -15°C

Max: +300°C78 IRHD Developed to meet severe service requirements where application conditions may involve high temperature use and/or sealing of water and steam. ZC501

Norsok M 710 Approved FFKMMin: -19°C

Max: +230°C89 IRHD This compound has been developed to meet the severe service requirements of the oil & gas industry.

Approvals: Norsok M-710 Rev 2 ApprovedZC700

Ultra Low Temp FFKMMin: -45°C

Max: +240°C93 IRHD Developed to meet the severe service requirements of the Oil & Gas industry Need some help?

Our technical department can help with further information on any of our seals, and help with selecting the correct material for your application.