Robotics Industry Sealing Solutions

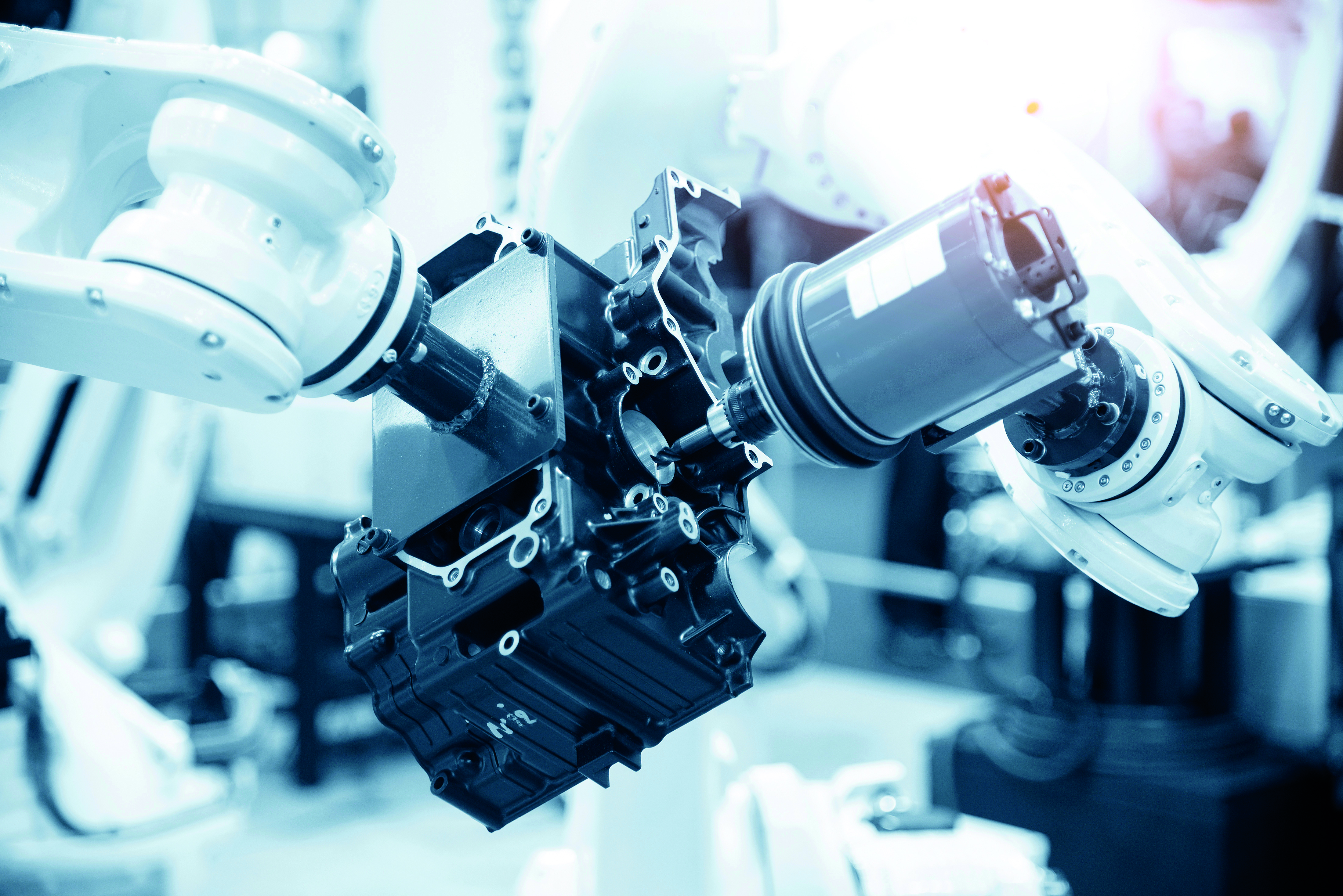

Protecting vital components from contamination, wear and environmental factors to enhance precision and performance.

Our high-performance sealing solutions for the robotics industry, offer innovative designs that support the complex and dynamic needs of modern robotic systems. Our seals are engineered to withstand the high demands of precision, reliability, and durability required in various robotics applications, from manufacturing robots to autonomous vehicles and industrial automation systems.

Robotic systems are built to operate in a wide range of environments – from industrial floors to cleanrooms and even outdoor conditions. Our sealing solutions are designed to protect crucial components from contamination, wear and factors such as dust, moisture, heat, and extreme mechanical stress. Whether you’re developing robotic arms, mobile robots, or precision automation tools, our seals ensure that your systems continue to operate at peak efficiency.

Robotics Sealing Products

O-Rings

Reliable sealing for robotic joints, actuators, and hydraulic components, preventing leaks and contamination. Available in a range of materials such as fluorocarbon, silicone and EPDM, our o-rings are ideal for both static and dynamic applications, ensuring tight seals in high-pressure or high-temperature environments.Rotary Seals

Essential for rotating parts in robotic systems, our rotary seals provide exceptional sealing for shafts, motors, and actuators. They are designed to prevent fluid leakage and protect against contamination while maintaining smooth rotation and high precision in critical robotics applications.Gaskets

Precision-engineered gaskets for robotic enclosures, battery compartments and control units. These gaskets are designed to prevent dust, moisture, and other contaminants from entering sensitive components, ensuring that your robot remains operational in harsh environments.Hydraulic Seals

For robots with hydraulic systems – such as robotic arms or autonomous vehicles – our hydraulic seals ensure leak-free operation. Designed to withstand high pressures and harsh conditions, they provide reliable performance and prevent downtime caused by seal failure.Custom Seals

Because each robotic system has unique requirements, standard seals may not always be suitable. Our engineered seals division can work closely with you to design custom seals that meet your specific needs, whether for highly specialised robotic equipment, high-precision applications, or systems working in extreme conditions.Sealing Materials for the Robotics Industry

Sealing materials are chosen based on application requirements such as flexibility, chemical resistance, wear resistance and temperature tolerance.

Some of the most commonly used sealing materials in robotics are:

Silicone Rubber (VMQ) - Excellent temperature resistance (-60°C to +230°C), good flexibility and biocompatible. Used in medical robots, food processing robotics, or high-temperature environments.

Fluorocarbon Rubber (Viton™/FKM) - Outstanding chemical resistance, high-temperature performance (up to 250°C). Used in chemical plants, automotive, and aerospace applications.

EPDM - Excellent resistance to weathering, ozone, water, and steam. Used in outdoor robotics, HVAC systems and applications requiring water resistance.

Nitrile Rubber (NBR) - Good resistance to oils and fuels, affordable. Used in hydraulic seals, pneumatic systems, and general-purpose sealing.

Polyurethane (PU) - High abrasion resistance, good mechanical strength. Used in robotic actuators and gaskets for moving parts.

PTFE (Teflon™) - Chemically inert, high thermal resistance, low friction. Used in robotic arms, chemical exposure environments and cleanrooms.

Sealing Applications in the Robotics Industry

Our sealing solutions are trusted by engineers and manufacturers working in various robotics applications, including:

- Industrial Robots - Seals for robotic arms, grippers, actuators, and conveyor systems in factories, assembly lines, and other manufacturing environments.

- Autonomous Vehicles - Seals for robotic systems in autonomous vehicles, including seals for sensors, actuators, and electrical compartments, ensuring protection against dirt, water, and environmental contaminants.

- Medical Robotics - Seals for surgical robots, diagnostic equipment, and robotic-assisted procedures, where precision and cleanliness are paramount for safety and reliability.

- Consumer Robotics - Seals for home robots, such as vacuum cleaners, lawn mowers, and personal assistants, protecting components from dust, moisture, and wear.

- Drones - Seals for drones and aerial robots to protect against the elements and ensure smooth operation of motors, sensors, and battery compartments.

How Seals Enhance Robotics Performance

Sealing solutions play a critical role in maintaining the reliability, efficiency, and precision of robotic systems:

- Protecting Critical Components: Seals prevent contaminants such as dirt, dust, moisture and chemicals from entering sensitive parts like motors, actuators and sensors, ensuring that robots operate smoothly and without failure.

- Enhancing Efficiency: High-quality seals reduce friction, prevent leaks and protect against wear, which helps robots maintain their performance over longer operational periods and reduces downtime.

- Ensuring Durability: Seals are engineered to withstand high pressures, temperatures, and harsh conditions, contributing to the longevity of robotic systems and reducing the need for costly repairs and maintenance.

- Increasing Precision: In robotics, even the smallest discrepancies can impact performance. Our seals ensure precise movements and system integrity by providing tight seals that prevent external elements from interfering with sensitive operations.

Why M Seals?

With over 60 years of expertise and a focus on quality, we offer sealing solutions that ensure your equipment operates efficiently and safely, no matter the environment.

- High quality sealing products for the robotics industry, protecting vital components from contamination, wear and environmental factors to enhance precision and performance.

- Fast turnaround – fast, reliable delivery and customer support.

- Quality assurance – we are certified in several areas for quality, health and safety and environmental management.

- Testing & Traceability - Detailed testing & reporting, with full traceability of materials and testing procedures.

- Custom solutions – we can design sealing solutions that meet unique operational needs, working directly with engineers to ensure that each seal fits seamlessly into your machinery, ensuring maximum performance and durability.

- Kitting – for your OEM spares requirements.

- In-house manufacturing- with 12 machines across M Seals locations globally and over 240 different engineered material grades in stock.

- High performance materials.

- Technical support and customer service – timely response to technical enquiries, troubleshooting of any issues and onsite support.

Any questions?

If you have any questions about seals for the robotics industry, please contact our technical team.