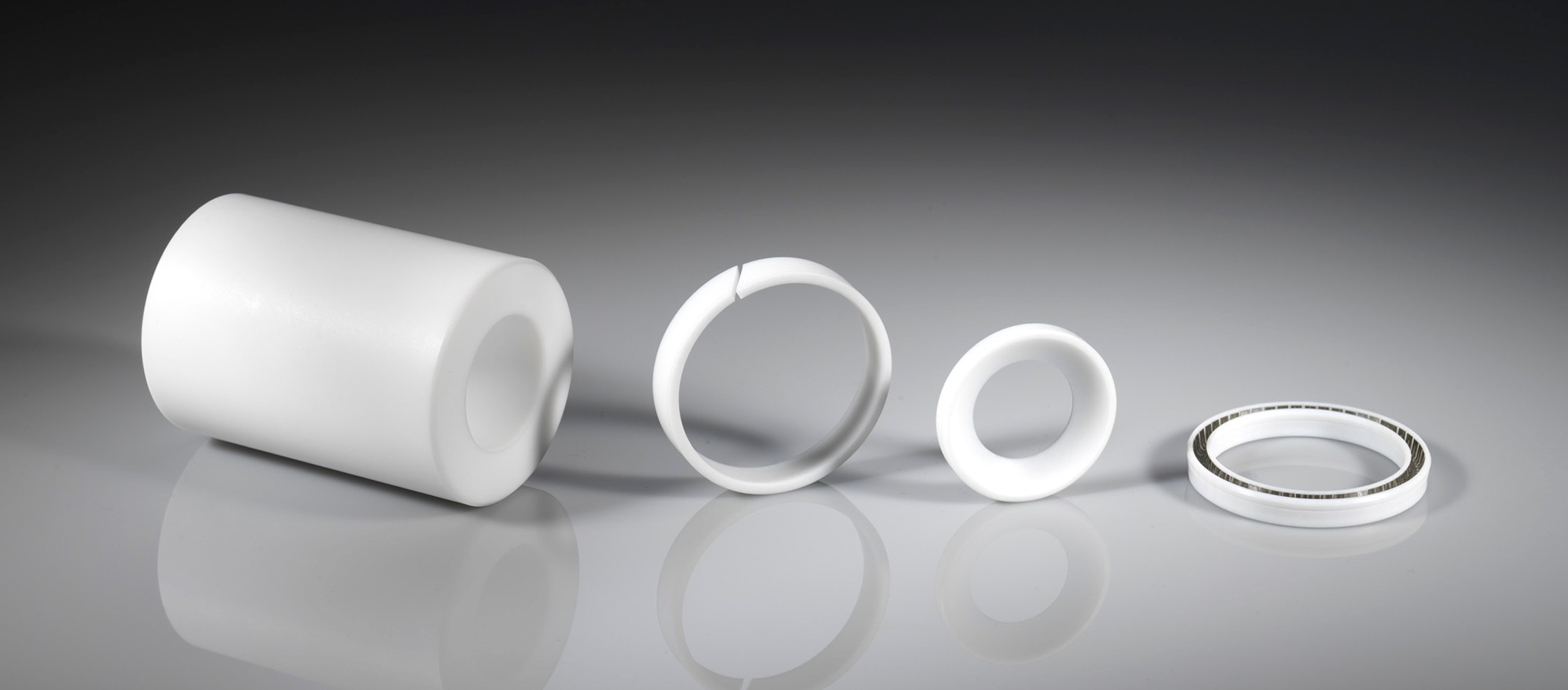

PTFE (Polytetrafluoroethylene)

PTFE (also called Teflon, polytetrafluoroethylene) is an exceptional polymeric material. It has exceptional qualities that are not found in elastomeric materials, making it a great choice for some of the most difficult applications. Not only because of its high chemical resistance, flexibility, and electrical and thermal resistance, but also because it’s an extremely cost-effective option for high-performance seals and O-rings.

What is PTFE?

PTFE is a particularly versatile plastic fluoropolymer with an ivory-white and opaque colour. On a molecular level, PTFE consists of a chain of carbon atoms with two fluorine atoms bonded to each carbon. These fluorine atoms surround the carbon chain, creating a dense molecule with strong carbon-fluorine bonds and a polymer structure that is inert to most chemicals.

Advantages of PTFE

Due to PTFE’s prevalent carbon-fluorine bonds, it offers high flexural strength as well as remarkable performance in the following areas:

- Chemically inert to most caustic fluids

- Resistance to practically all known fluids

- High electrical resistance and dielectric strength

- Superior chemical resistance

- Excellent temperature ranges from -30°C to +200°C

- Low co-efficient of friction of any solid

- No explosive decompression damage

- Extremely weatherable and non-adhesive

- Water resistant

- Unlimited shelf life

- Easy to clean

PTFE is also a cost-effective elastomeric option for seals and O-rings.

PTFE seals can function in both static and dynamic reciprocating applications, and PTFE makes an ideal choice for high-speed rotary seals. PTFE is suitable for a wide range of applications in industries such as aerospace, food & beverage, pharmaceutical & healthcare and pneumatic & hydraulic.

Filled PTFE

Although PTFE has exceptional chemical and thermal resistance properties, in its unfilled or virgin form, it provides limited mechanical benefits. It’s a very soft material that can deform under a load. However, the mechanical properties of Virgin PTFE can be enhanced through the introduction of various fillers to the compound.

Adding a filler to PTFE can increase its strength, improve resistance to abrasion and also add electrical conductivity

M Seals offer a wide range of fillers to help improve the mechanical properties of Virgin PTFE. These include but are not limited to:- Glass fibre filled PTFE

- Carbon and Carbon Graphite filled PTFE

- Bronze filled PTFE

- Carbon Fibre filled PTFE

- Mineral filled PTFE

- Polyimide filled PTFE

- Ekonol® filled PTFE

- Plus many others, including some proprietary compounds.

FDA compliant

Certain types of PTFE are recognised as being suitable for use with foodstuffs and meet stringent Food and Drug Administration (FDA) requirements.

- PTFE 501 REV2113.1 KB

- PTFE 503 50494.7 KB

- PTFE 50794.7 KB

- PTFE 50997.2 KB

- PTFE 51095.2 KB

- PTFE 512 REV A99.8 KB

- PTFE 51395.1 KB

- PTFE 51442.4 KB

- PTFE 51895.0 KB

- PTFE 519 REV B100.4 KB

- PTFE 52893.7 KB

- PTFE 53085.2 KB

- PTFE 53692.3 KB

- PTFE 53792.8 KB

- PTFE 54042.4 KB

- G PTFE 598 Rev4100.9 KB

- PTFE 59997.7 KB

- MSDS PTFE2.4 MB

Ask our specialists

If you have any questions about PTFE or any other materials, please don't hesitate to talk to our technical team.