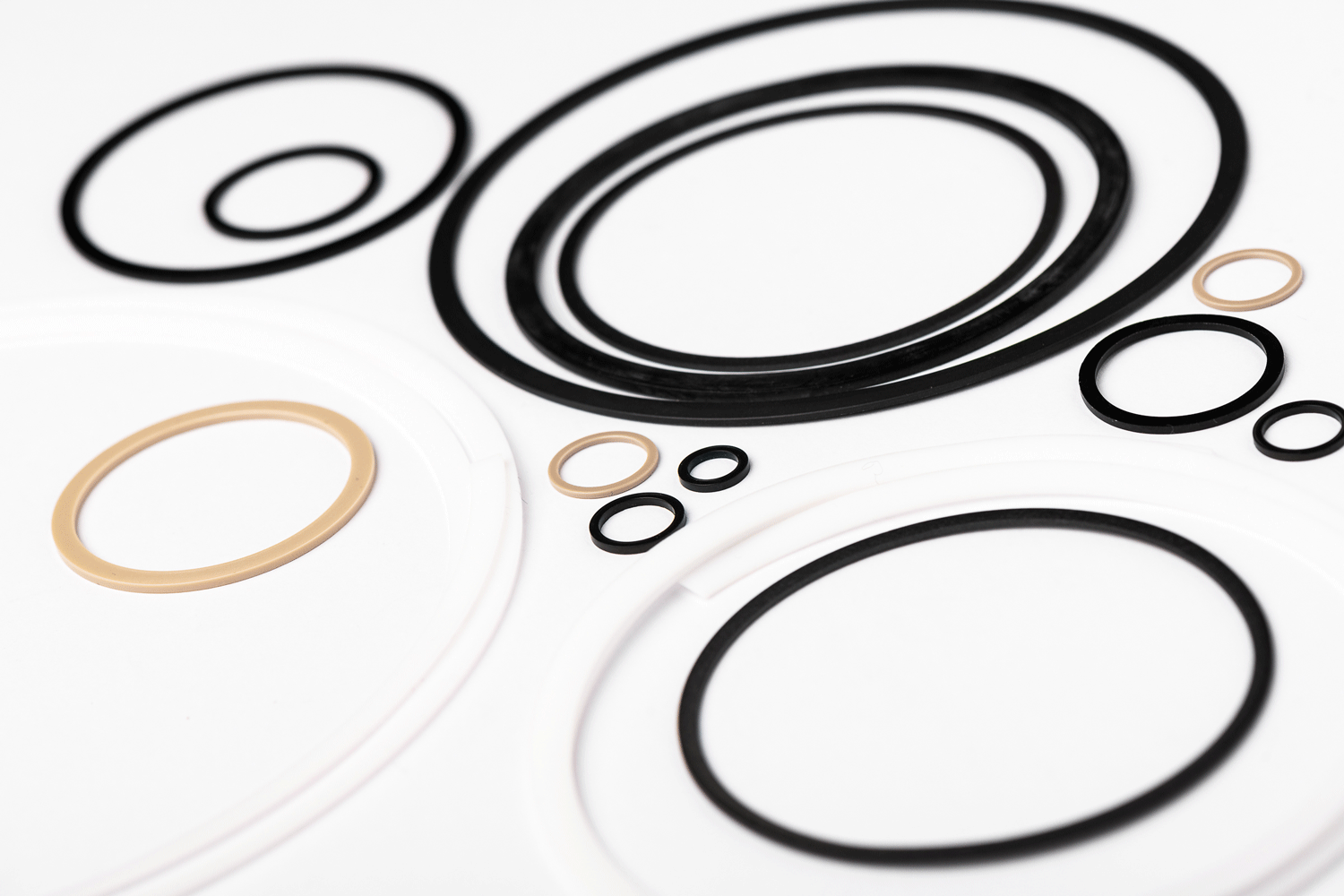

Back-Up Rings

Back-up rings work by preventing the extrusion of the primary seal under high pressure or high temperature conditions, ensuring a tight seal between the piston or rod and the cylinder. They also help to distribute pressure evenly across the sealing surface, which can prolong the life of the primary seal.At M Seals we offer a wide range of high-quality back-up rings that are compatible with various types of hydraulic and pneumatic systems.

High quality materials for superior performance

PTFE, or polytetrafluoroethylene, is a popular material for back-up rings due to its exceptional chemical resistance and low coefficient of friction. Back-up rings made from PTFE are ideal for use in applications where aggressive chemicals or high temperatures are present, as they can withstand a wide range of corrosive and abrasive fluids. PTFE back-up rings also offer excellent resistance to extrusion and wear, which helps to prolong the life of the primary seal and prevent leaks in your hydraulic or pneumatic system.

In addition to PTFE, there are several other materials commonly used for back-up rings, including:

Request a Quote

Polyurethane: Back-up rings made from polyurethane offer excellent resistance to wear, abrasion and high pressures. They are also known for their high load-bearing capacity and low compression set, which makes them ideal for use in heavy-duty applications.

Nitrile rubber: Nitrile rubber back-up rings offer excellent resistance to oil, grease and other hydrocarbons. They are also highly durable and resistant to abrasion, making them suitable for use in demanding applications.

Silicone: Silicone back-up rings are ideal for use in high-temperature applications, as they can withstand temperatures of up to 200°C. They are also highly resistant to ozone and UV light, which makes them suitable for use in outdoor environments.

Fluorocarbon: Back-up rings made from fluorocarbon are highly resistant to heat, chemicals, and oils, making them ideal for use in high-temperature and high-pressure applications.

Benefits of using back-up ringsUsing back-up rings in your hydraulic or pneumatic system offers several benefits, including improved seal life, reduced downtime and lower maintenance costs. By providing additional support to the primary seal, back-up rings can significantly extend the life of the seal and prevent extrusion, which can cause leaks and system failures. This results in less downtime and lower maintenance costs, which can improve the overall efficiency and profitability of your operation.

How back-up rings workThe primary seal is typically made from an elastomeric material, such as rubber or polyurethane, and is designed to conform to the surface of the piston or rod to create a tight seal. However, under high pressure, the primary seal may deform or extrude into the clearance gap between the piston or rod and the housing, causing it to fail and allow fluid to leak past the seal.

The job of a back-up ring is to prevent this happening. They are installed on either side of the primary seal to provide support and prevent extrusion. Back-up rings work by distributing the pressure evenly across the sealing surface, which helps to prevent the primary seal from deforming or extruding. They also act as a barrier, preventing fluid from seeping through the clearance gap and past the primary seal.

Solid vs. split back-up ringsThe main difference between solid and split backup rings lies in their installation and removal process. Solid backup rings require disassembly of the system to install or replace them, while split backup rings can be inserted or removed without dismantling the entire system. Split backup rings are advantageous in applications where frequent maintenance or seal replacement is required, as they offer a more convenient and time-saving solution.

Solid back-up rings are typically used in applications where the primary seal is difficult to access, or where the back-up ring needs to be installed prior to the primary seal. They offer excellent support to the primary seal and distribute pressure evenly across the sealing surface, which helps to prevent extrusion and prolong the life of the seal.

Split back-up rings, on the other hand, are designed to be installed around the piston or rod after the primary seal has been installed. This makes them an ideal solution for applications where the primary seal is easily accessible or where frequent maintenance is required. Split back-up rings are also easier to install and remove compared to solid back-up rings, which can save time and reduce maintenance costs.

Spiral back-up rings

Spiral back-up rings are a highly effective solution for preventing extrusion and improving the performance of your hydraulic or pneumatic system. Made from premium materials, such as polyurethane or nitrile rubber, spiral back-up rings are designed to withstand high pressure and temperature conditions, ensuring a tight seal between the piston or rod and the cylinder. With their unique spiral design, spiral back-up rings provide superior support to the primary seal and distribute pressure evenly across the sealing surface, which can significantly prolong the life of the seal.

Custom solutions for your unique application

We understand that each hydraulic or pneumatic application is unique, which is why we offer custom back-up ring solutions tailored to your specific needs. Our team of experts can help you design and manufacture a custom back-up ring that meets your application's unique requirements, ensuring optimal performance and reliability.

Expert technical supportWe have the knowledge and experience to help you select the best back-up ring for your application, whether you need a custom solution or a standard back-up ring. Speak to our team to discuss how our back-up ring solutions can help you improve the performance and reliability of your system.