Metal O-Rings

M Seals offers a comprehensive range of premium metal O-rings, designed to deliver secure and reliable sealing for vacuum, gas, and liquid applications. Engineered to perform exceptionally well under even the most extreme conditions, our metal O-rings are ideal for ultrahigh vacuum environments and can withstand pressures up to 5500 bar.

Built for durability and versatility, our metal O-rings operate efficiently across a broad temperature spectrum, from -269°C to +750°C. They also provide outstanding resistance to radioactive radiation, chlorides, corrosion, and other aggressive substances. Remarkably resilient, our O-rings maintain superior performance over time, showing no signs of aging during use or storage.

Globally recognised for their reliability in the harshest operating conditions, our metal seals are the solution when conventional sealing products fall short. Whether dealing with temperature extremes, flange gaping, or achieving the necessary leakage rates, our metal O-rings excel where traditional seals cannot.

Key Features

- Seals vacuum, gases, and liquids under extreme conditions, withstanding pressures from UHV up to 5500 bar and temperatures ranging from -269°C to 750°C.

- Resistant to radioactive radiation, chlorides, corrosion, explosive decompression, and other aggressive influences, with no aging over time.

- Offers customisable solutions to meet specific application requirements, achieving the lowest leakage rates through additional coatings.

- Ensures tightness even with flange gaping due to the elastic compensation behaviour of the seal.

- Simplifies force calculations by operating in a force shunt.

Request a Quote

Metal O-Ring Types

Each type of metal o-ring is suited for specific applications, offering various sealing solutions to meet diverse requirements.

METAL O-RING TYPES

Pressure

Vacuum up to 6.8 barStandard Metal O-Ring

Manufactured from various metallic tubing or solid wire, this metal o-ring is an economical choice for applications with low to moderate pressure or vacuum ratios. It is not self-energising or pressure-filled.

Pressure

6.8 bar and aboveSelf-Energising Metal O-Ring

Features grooves and bores on the inner or outer diameter, enabling the O-ring to experience the same pressure as the system. This design utilises system pressure to enhance sealing performance.

Pressure

Vacuum to approx. 20 barPressure-Filled Metal O-Ring

Engineered specifically for high-temperature applications ranging from 425°C to 980°C, these O-rings are filled with gas at pressures of approximately 40 bar or higher. As temperatures rise, the gas pressure increases, compensating for any initial tension deficiencies in the flanged joint and boosting the sealing force. Although they offer lower pressure resistance than self-energising types, they are exceptionally effective in high-temperature environments.Metal O-Ring Materials

SS321 (Stainless Steel 321)

Maximum Service Temperature: 371°CThis stainless-steel variant is stabilized with titanium, which prevents chromium carbide precipitation at temperatures above 371°C. This stabilization makes SS321 significantly more resistant to intergranular corrosion compared to other stainless-steel types.

Inconel 600

Maximum Service Temperature: 538 °CInconel 600 is a nickel-chromium alloy valued for its excellent oxidation resistance at moderate service temperatures. It also demonstrates strong resistance to carburizing and chloride-containing environments. The alloy's high nickel content offers protection against reducing environments, while its chromium content ensures resistance to weaker oxidizing conditions, making it ideal for corrosion-resistant applications.

Inconel X-750

Inconel X-750 is an age-hardened, nickel-based superalloy renowned for its exceptional high-temperature strength and corrosion resistance. It excels in extreme conditions, providing excellent tensile and creep rupture properties, with optimal strength achieved between 700°C and 975°C. Generally, stainless steel such as SS321 is more cost-effective than nickel-based alloys like Inconel, making SS321 a more economical option when budget is a key consideration.Metal O-Ring Coating

Coating or electroplating a metal O-ring improves adhesion and creates a softer surface, allowing it to conform to microscopic imperfections in the groove or flange. When compressed, the coating fills these irregularities, enhancing the seal. The leakage rate depends on the coating, the ring's interaction with the surface, and the quality of the groove and flange. The coating's necessity and thickness are determined by the desired leakage rate and surface quality, ensuring the seal matches the ring's pressing load for optimal performance.

Coating Materials

Copper A soft material that enhances sealing performance and reduces leakage rates. It provides good corrosion and tribo-oxidation resistance, making it ideal for steel rings where lubrication is crucial. Silver Offers superior oxidation and chemical resistance. It is cost-effective, adheres well, and is suitable for high-temperature applications. Silver improves operational safety and is a more affordable option than gold coating. Tin Improves leakage rates and smooths the surface of metal seals. It offers moderate corrosion resistance and good gas barrier protection but is limited in high-temperature applications. PTFE This polymer layer provides excellent sliding properties, low friction, and high elasticity. It offers superior corrosion resistance and is ideal for aggressive environments. Gold Known for exceptional corrosion resistance, wear resistance, and workability, gold is suitable for high-temperature and dynamic operations. Nickel Provides high hardness, wear resistance, and excellent corrosion resistance. It's ideal for high-temperature and high-pressure applications, reducing the static friction of metal seals and protecting the base metal from corrosion. Ring Diameter & Tube Wall Thickness

The tube profile section is determined by the outside diameter of the rings, the desired force of pressure and the available space. The wall thickness must be selected so that an adequate force of pressure accrues upon the appropriate deformation. The following data shows the common wall thicknesses, which can be applied for each diameter.

With electroplated surfaces, seals with a tube wall thickness ≥ 3.2 mm diameter and load of approx. 72 N/mm peripheral length leads to a plastic deformation of the electroplating. For tubing with a diameter ≤ 3.2 mm a pressing of 140 N/mm peripheral length is required. Teflon coatings on rings are plastically deformed with a load of 18 N/mm peripheral length.

Tube outside diameter (mm) Ring outside diameter (mm) Standard tube wall thicknesses (mm) min. max. 0.9 6.4 101 0.15 1.6 15.9 254 0.25 / 0.36 2.4 25.4 508 0.25 / 0.46 3.2 50.8 1016 0.25 / 0.51 4.0 76.2 1270 0.51 / 0.64 4.8 101.0 1524 0.51 / 0.81 6.4 127.0 2500 0.64 / 0.81 Groove Dimensions

The correct groove size and surface finish are just as important as the O-ring for effective sealing. The recommended groove dimensions for internal and external pressure applications provided below serve as general guidelines for preparing sealing surfaces.

Tube outside diameter (mm) Groove depth (mm)

min-maxGroove width (mm)

min.Ring tolerance (mm) Average Seating Load (F)(N/mm) Groove outside dia. (mm)

(for internal pressure)Groove inside dia. (mm)

(for external pressure)0.9 0.60 - 0.68 1.4 0.08 70 B+0.10 / 0.20 A-0.10 / 0.20 1.6 1.15 - 1.25 2.3 0.08 110 B+0.10 / 0.20 A-0.10 / 0.20 2.4 1.80 - 1.95 3.2 0.13 60 B+0.15 / 0.25 A-0.15 / 0.25 3.2 2.40 - 2.60 4.2 0.13 40 B+0.20 / 0.35 A-0.20 / 0.35 4.0 3.05 - 3.25 5.2 0.15 115 B+0.25 / 0.40 A-0.25 / 0.40 4.8 3.70 - 3.90 6.4 0.18 95 B+0.25 / 0.40 A-0.25 / 0.40 6.4 5.00 - 5.20 8.5 0.20 110 B+0.30 / 0.50 A-0.30 / 0.50 Quality of Finish

Recommended surface finish qualities for the groove and flange jointing face are as follows:

- 0.1 to 0.4 µm Ra for uncoated rings

- 0.4 to 0.8 µm Ra for electroplated or coated rings

- 0.2 to 0.6 µm for vacuum or gas applications

Ghost lines on the groove surface or flange face must be clean and free of dirt, grinding dust, or other contaminants. The following surface roughness levels are commonly used in practice:

Surface Roughness (μm) Coated O-Ring Uncoated O-Ring Ra = 0.4 - 0.4 to 0.8 μm Ra = 0.1 - 0.4 μm Ra Metal O-Ring Fitting

Internal pressure application

Outer diameter of the ring (ODR) is calculated as: ODR = OD - Z

External pressure application

Outer diameter of the ring (ODR) is calculated as:

ODR = ID + Z + 2*CSR + (4*Pt)

(4*Pt) only valid for rings with coating

CSR Nominal cross-section: cross-sectional dimension (without coating) e.g. similar to the cord thickness of elastomer O-rings Code Performance Index: shows characteristics of the ring (e.g. pressing load, springback) D Groove depth: axial design dimension to which the ring is pressed from the original cross-section CSR. F Pressing load: the mentioned guide values refer to 1mm seal length. To obtain the total load of the seal for the design of the construction, this value must be multiplied by the circumferential length of the seal. ID Inner diameter of the groove: reference dimension for external pressure applications OD Outside diameter of groove: reference dimension for internal pressure applications. ODR min. Outside diameter of the ring: The outside diameter of the ring is freely selectable from the mentioned minimum dimension ODR min. and is at the same time the corresponding dimension to the outside or inside diameter of the groove. Pt Coating thickness R Radius: Design dimension that improves the support of the ring under pressure SB Springback: maximum possible measure by which the ring can spring back elastically overall. Important value in connection with possible flange gaps. Wmin Groove width: radial design minimum dimension. The specified minimum dimension Wmin. must not be undercut. Wt Wall thickness: sheet thickness of the ring. Z Diametric clearance between ring and groove. Seating Loads Required

To determine the average seating or pressing load required for a metallic seal, refer to the provided guide values. These values are given per millimetre of circumference, so the total load needed to seat the ring is calculated by multiplying this value by the circumference of the ring (i.e., the total length of the seal). This load will seat the ring at atmospheric pressure, and additional loading will be necessary to accommodate the system's operating pressure.

Please contact our technical department for further information.

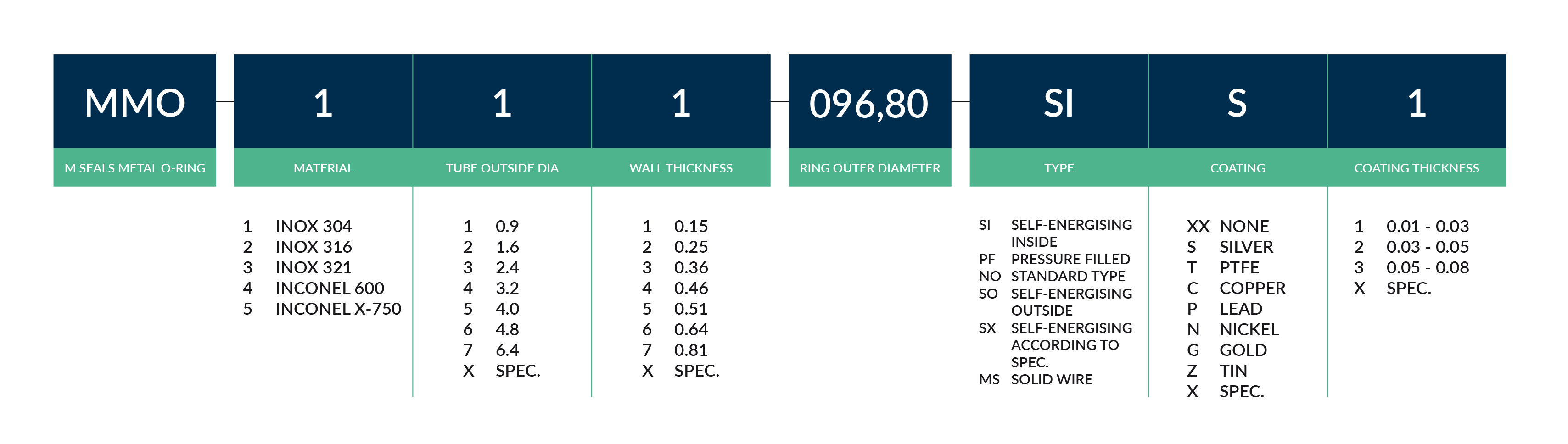

How to Order Metal O-Rings

We ask that you provide as much information as possible to specify the correct metal o-ring for your application. If you do not have this information, our team of technical experts can help.

Please complete the form above with as much detail as you can, and we will get back to you as soon as possible.