X-Rings / Quad Rings

X-rings, also called Quad Rings, are used in hydraulic and pneumatic systems, automotive engines and industrial machinery. Their four-lobed design provides superior sealing compared to traditional O-rings, with four sealing surfaces instead of two.

The symmetrical shape withstands stress from multiple directions, with increased pressure causing radial expansion and progressive sealing. X-rings require less squeeze, reducing friction and extending service life. Parting lines are positioned between lobes, keeping sealing surfaces free of defects that could cause leaks. The square profile prevents twisting, often outperforming O-rings in rotating applications.

X-Rings Catalogue

For detailed product information and technical data:

X-Ring Characteristics

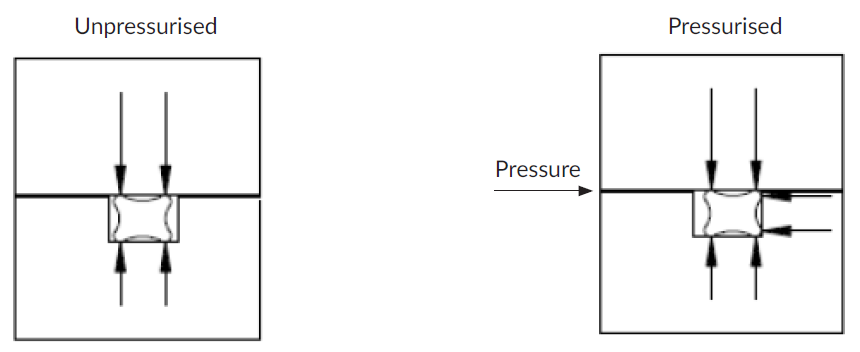

The X-ring is a symmetrical 4 lobe seal, with a square fitting cross section.

The inner diameter (I.D) and the width of the cross section (C.S.) are the dimensional characteristics of the X-ring.Because of its symmetrical shape, the X-ring can withstand any stress from any direction. An increase in pressure leads to a radial section increase and then to a progressive constraint of the seal.

Application conditions, standard material NBR 70

Pressure Dynamic

No back-up ring

≤ 50 bar

With back-up ring

≤ 300 bar

Pressure Static

No back-up ring

≤ 50 bar

With back-up ring

≤ 400 bar

Temperature -30°C to +100°C

Sliding speed for linear movement ≤ 0.5 m/s

Advantages of X-rings

- Superior sealing performance - reduces risk of leaks and premature failure

- Increased resistance to twisting and rolling

- More resistant to extrusion

- Lower friction and wear - longer service life and reduced maintenance costs

- Can operate at higher speeds than O-rings

Applications of X-rings

- Hydraulic and pneumatic systems

- Industrial machinery and equipment, such as pumps, compressors, and gearboxes

- Automotive industry - in engines, transmissions, steering systems, suspension systems

- Aerospace and defence industries - in jet engines, hydraulic systems and fuel systems

- Medical and pharmaceutical industries - in pumps, valves and medical devices.

Selecting materials for X-ringsNBR (Standard Material)

NBR grades have good resistance to mineral oils and fats, especially hydraulic oils, gasoline and similar aliphatic hydrocarbons, water, ethylene glycol, acids and alkalis. Good mechanical properties such as high wear resistance and good compression set ensures this elastomer a wide scope.

Temp. -40° to + 100° C.FPM (On Request)

Extraordinary high resistance to mineral oils, aliphatic, aromatic and chlorinated hydrocarbons, concentrated and dilute acids. Very high temperature, aging resistance, good compression set and good mechanical properties make this elastomer particularly useful, where maximum life of elastomers is required.

Temp. -30° to + 200° C.EPDM (On Request)

Excellent aging and ozone resistance. Good thermal properties. Excellent resistance to hot water and steam. Highly resistant to many organic liquids. Not resistant to petroleum oil and grease.

Temp. -50° to + 120° C.Contact us

If you have any questions or enquiries, please don't hesitate to get in touch with us. Our team is always here to assist you with any technical enquiries.